Consistent Quality with 10x Efficiency

Dobot's cobots have max speed of 4 m/s and are MTBF 30000 hour certified. Cobots can reliably complete assembly tasks with 10 times the efficiency compared to manual labor. 0.02 mm repeatability ensures consistency of assembled quality.

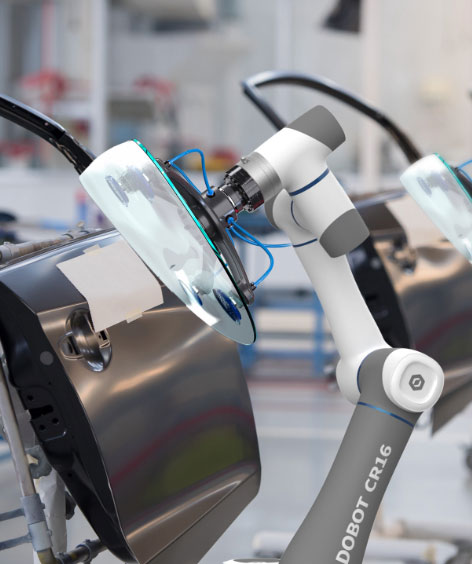

Auto Adapt to Complex Assembly Tasks

Our cobots are compatible with popular plug and play grippers, sensors and other accessories, to satisfy various assembly needs. For more delicate tasks, force sensors can be equipped on cobots for more accurate assembly performance.

Flexible Without Secondary Development

Cobots are easy to learn and operate. Program cobots via drag to teach or graphical user interface. Compared to traditional stationary automation devices, cobots are faster to deploy and quicker to switch between production lines. Change cobot behaviors with modular software instead of rewriting custom programs. Cobots are ideal for small batch flexible production.