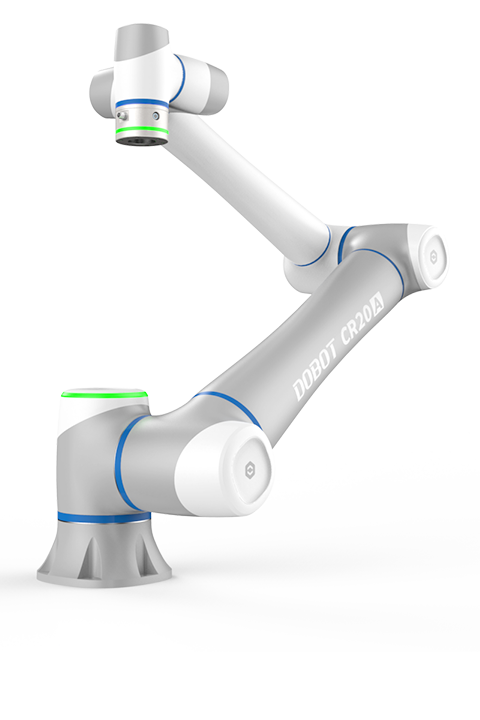

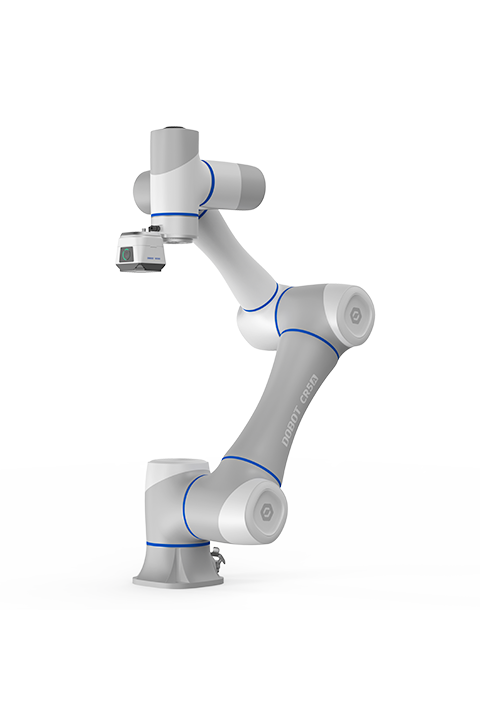

A key component of the solution was the integration of Dobot Cobot, a collaborative robot (cobot), with an Automated Guided Vehicle (AGV). This innovative setup allowed for a 7×24h working round-the-clock operation, providing smarter automation and higher accuracy in the inspection process.

The Dobot Cobot featured several advanced capabilities, including IP54 protection, a repeatability accuracy of 0.02mm, and the integration of True Motion Dynamics Algorithm and Vibration Suppression Algorithm. Additionally, the cobot was certified for Class-100 Cleanliness, making it well-suited for the provider's laboratory environment.