In the automated palletizer process, selecting the correct robot gripper is one of the key steps to customize your palletizing solution.

You may have different specific needs, such as large freight, fragile goods, or hazardous materials, there is a palletizing gripper suitable for nearly every operation.

Why You Need to Attach Importance to Palletizing Gripper?

Choosing the right gripper can make the difference between a smooth, efficient palletizing process and one plagued by damaged goods, unstable loads, and other issues. The gripper needs to be able to reliably pick up, hold, and place the specific products you need to palletize, without causing any harm.

Some key factors to consider when selecting a palletizing gripper include:

- Product Characteristics: The size, weight, surface material, and fragility of your products will dictate the type of gripper needed. Delicate items may require a soft-jaw gripper, while heavy machinery may need a heavy-duty vacuum gripper.

- Pallet Configuration: The way you need to stack items on the pallet, such as pattern, height, and overhang, will impact gripper choice. A gripper with adjustable fingers may be required for complex pallet layouts.

- Operational Requirements: Palletizing speed, the need for precision placement, and safety concerns for hazardous materials will guide the selection of the appropriate gripper technology.

Different Grippers for Different Palletizing Tasks

There are a number of different categories of grippers. Each type is suited to different jobs, but most have an important role to play in the palletizing process.

Mechanical Grippers for Heavy-duty Tasks

Mechanical grippers use jaws or fingers to physically grasp the product. These are well-suited for handling rigid, uniform items like boxes or crates. Mechanical grippers can provide high grip force and are often used for heavy-duty palletizing.

Vacuum Cups for Smooth Surfaces

Vacuum grippers use suction cups to lift products by creating a vacuum seal. These are ideal for handling smooth, non-porous surfaces like plastic or glass. Vacuum grippers excel at picking up large, flat items and can provide delicate handling for fragile goods.

Dobot cobots offer both single-cup and dual-cup vacuum gripper options for palletizing. The single-cup vacuum gripper can achieve a picking speed of up to 8 pieces per minute, while the dual-cup vacuum gripper can reach speeds up to 13 pieces per minute. The multiple suction cups allow the gripper to securely lift larger or more awkwardly shaped items.

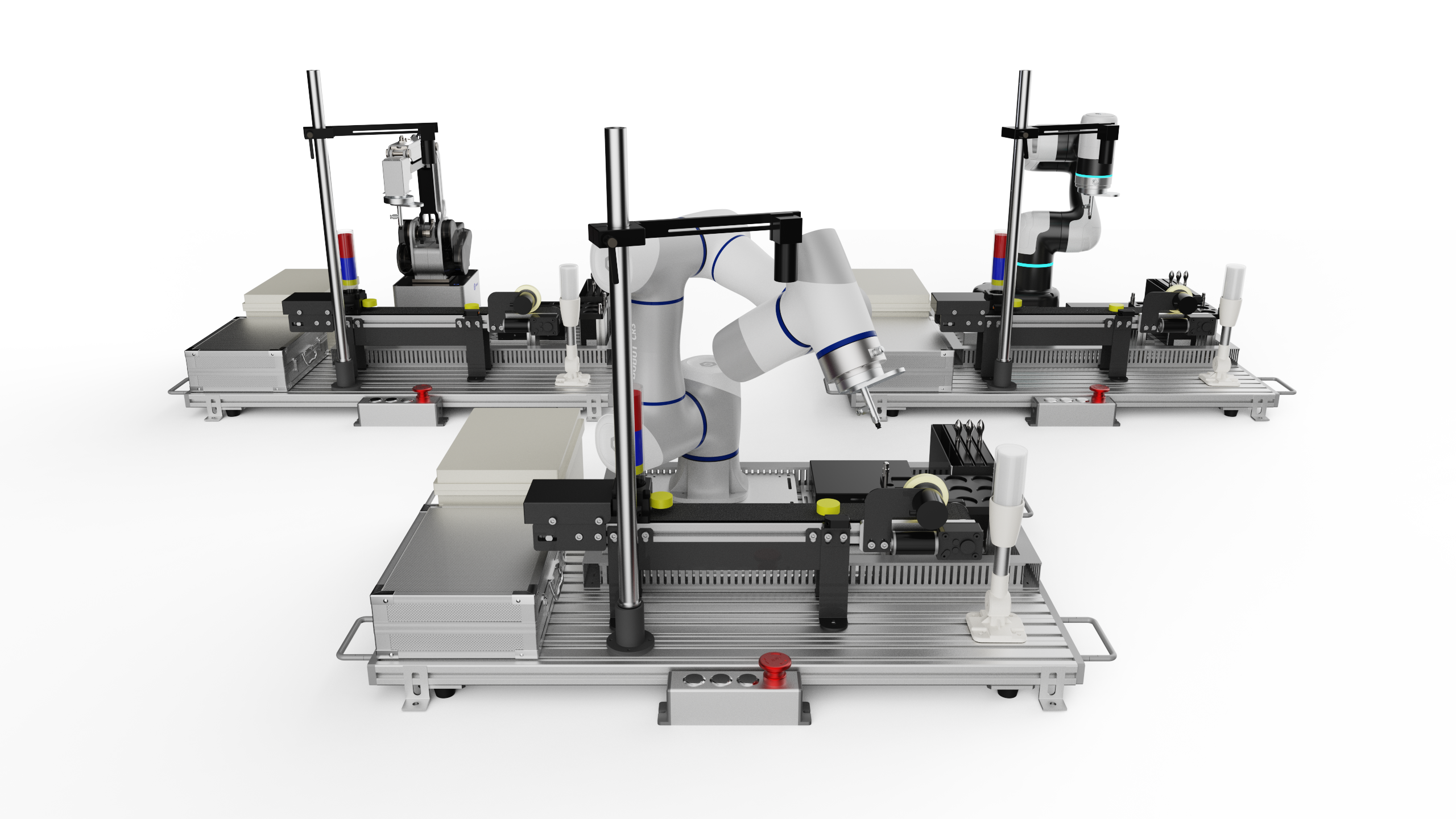

Dobot Palletizer Cobot in Dual Suction Cup Mode

Magnetic Grippers for Metal Objects

Magnetic grippers use electromagnetic force to lift ferrous metal products. These are commonly used for palletizing steel coils, metal sheets, or other heavy metallic items.

Pneumatic Grippers with Wide Compatibility

Pneumatic grippers use compressed air to open and close their gripper fingers. They offer fast response times and can handle a wide range of part sizes and weights. Pneumatic grippers are a popular choice for palletizing a variety of products.

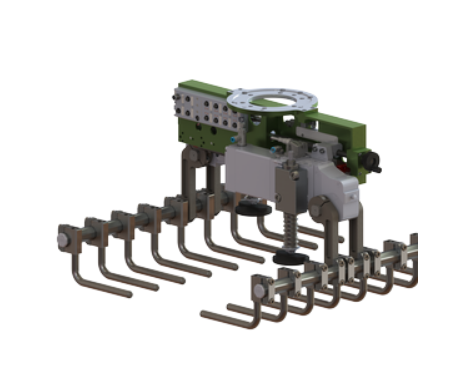

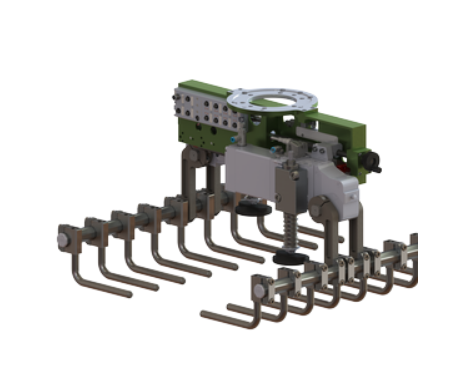

Fork Grippers for Enhanced Clamping

Fork grippers are a versatile option for the palletizing process. Their forked "fingers" are designed to slide under pallets, allowing them to securely grasp and lift entire palletized loads. This makes fork grippers well-suited for tasks like transporting full pallet stacks.

Beyond just moving pallets, fork grippers can also play a valuable role in other palletizing applications. For example, they can be used to clamp and hold open bags or boxes, helping to maintain proper alignment as products are loaded. And during depalletization, fork grippers can stabilize containers while the contents are unloaded.

While fork grippers are commonly paired with heavy-duty industrial robots, they can also be integrated with collaborative robots (cobots) to add this clamping capability to palletizing setups.

Precision Grippers for “Soft” Objects

Not all palletizing jobs involve large, sturdy items. Some products require a more delicate touch, whether due to their small size, fragile nature, or need for precise placement on the pallet.

This is where precision grippers come into play. These advanced grippers use sophisticated sensors and control systems to provide extremely accurate and repeatable part picking and placement. This makes them well-suited for handling delicate items or arranging complex pallet patterns that demand tight tolerances.

Precision grippers can employ soft, padded jaws or multiple suction cups to gently grasp and lift fragile or irregularly shaped products. This gentle approach helps prevent damage during the palletizing process.

Specialized Grippers

There are also specialized gripper designs for unique palletizing needs, such as:

- Soft-jaw grippers with padded surfaces for fragile items

- Multi-axis grippers that can rotate or tilt loads

- Grippers with sensors to detect and handle hazardous materials

Ultimately, the "best" palletizing gripper will depend on the specific requirements of your operation. Carefully evaluating your palletizing needs and working with an experienced automation provider can help you select the optimal gripper solution.