In today's fiercely competitive 3C (Computer, Communication, and Consumer Electronics) industry, did you know that over 70% of leading companies have already embraced robotic automation? Industry giants like Foxconn, Apple, and Samsung Electronics have integrated collaborative robots (cobots) into their production lines, leading to more than a 50% increase in production efficiency.

Isn't your company looking to gain the same competitive edge? As market demands evolve and production costs rise, robotic automation is becoming the key to boosting efficiency and ensuring product quality in the 3C industry.

How can cobots transform 3C production environments where repetition, speed, precision, and consistency are crucial?

1. Sorting

Cobots paired with vibratory bowls and vision systems are streamlining the handling of unordered materials in 3C manufacturing. When sorting tiny components, cobots ensure that every piece is picked, placed, and assembled with precision, drastically reducing the risk of errors.

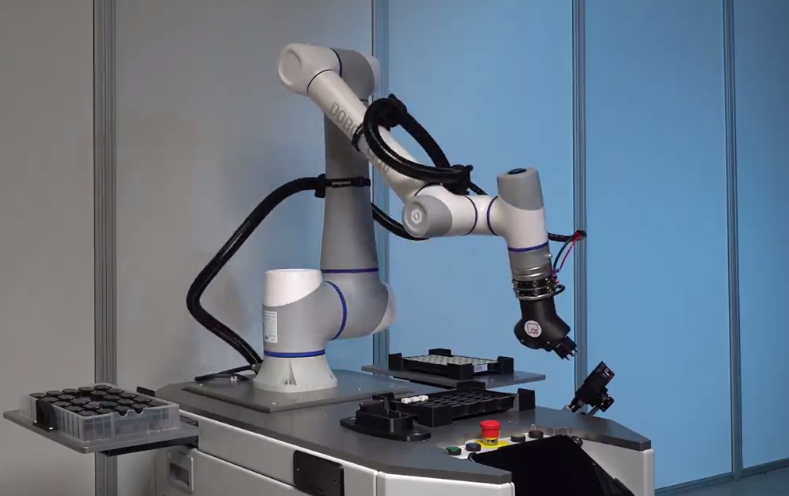

MG400 Sorting

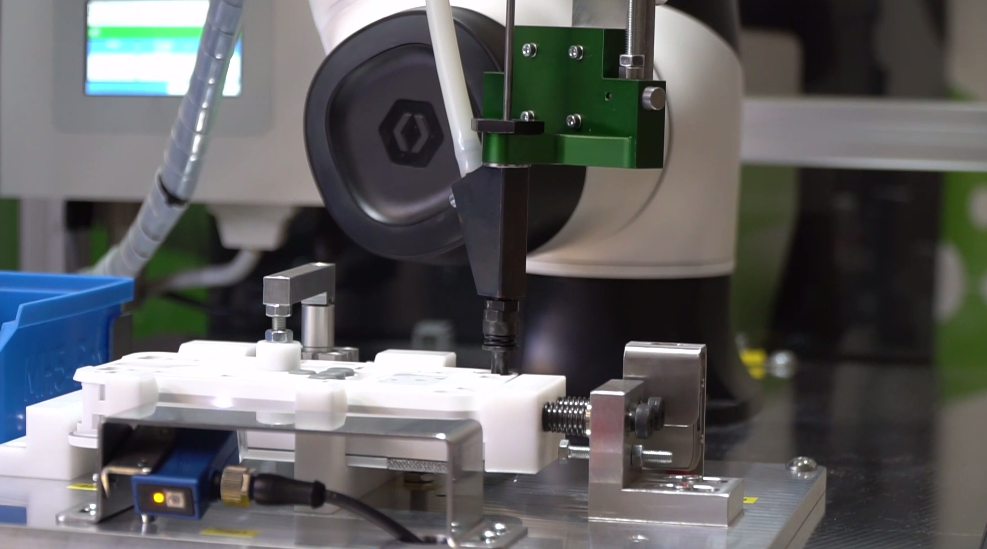

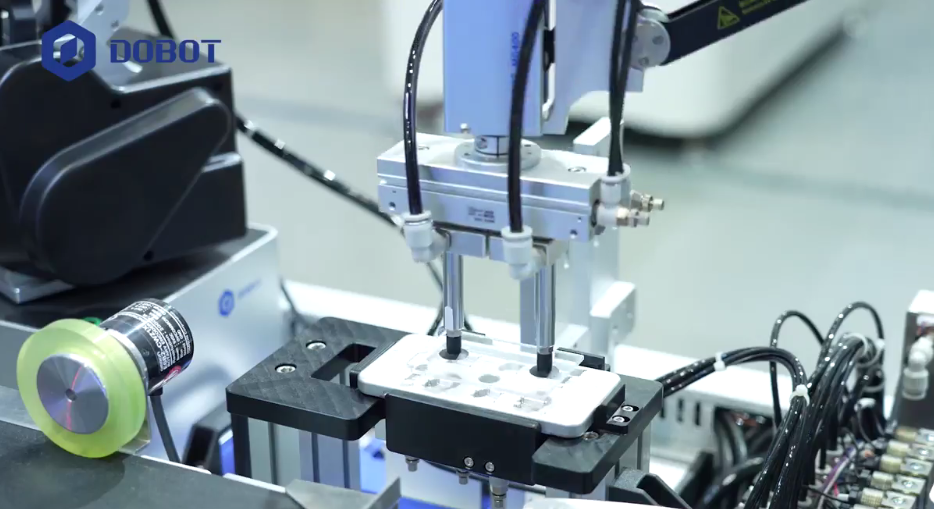

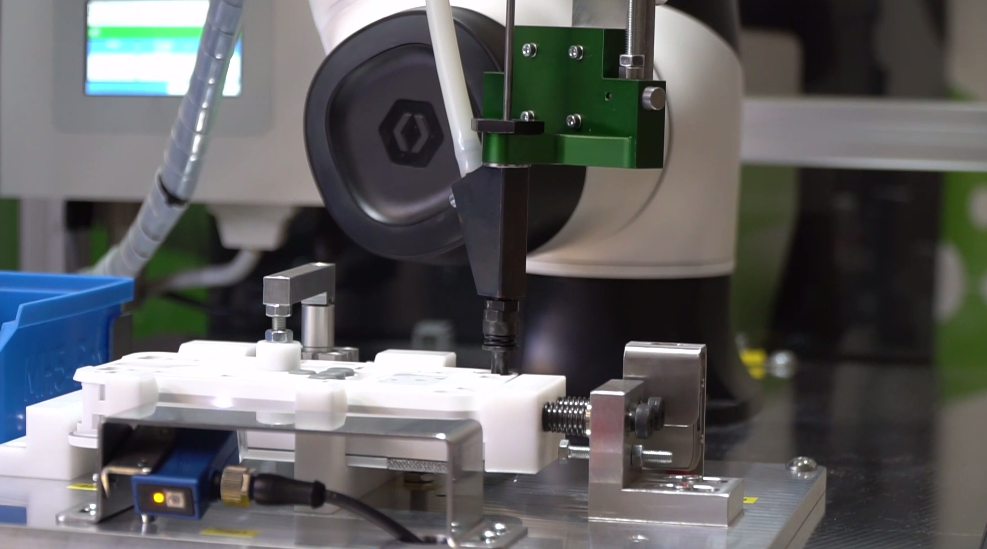

2. Screwdriving

Cobots equipped with screwdriving tools can adjust the torque applied to each screw, ensuring that it is tightened to the correct specification without damaging surrounding components. Cobots can operate in confined spaces and handle small screws with high accuracy.

CR Cobot Screwdriving

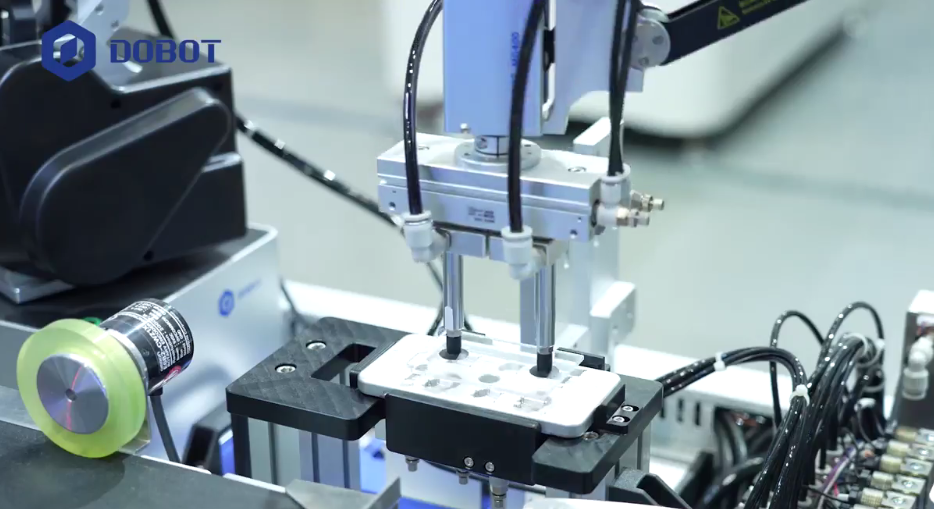

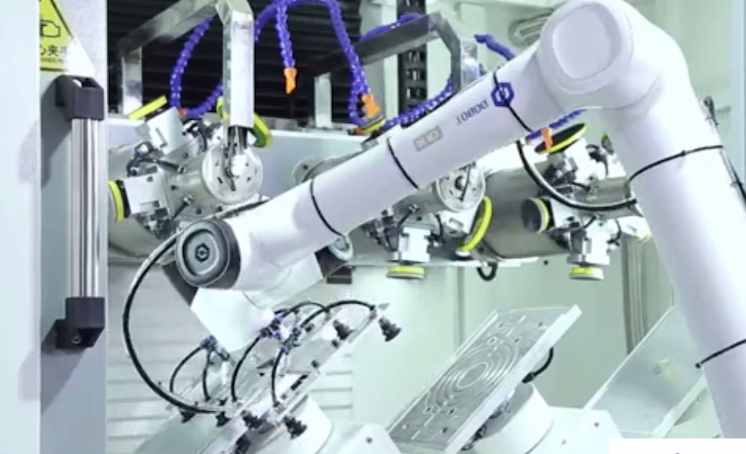

3. Assembly

Cobots paired with pneumatic grippers can load components onto the workbench. The cobots handle the precise placement of these components. This collaborative approach combines the efficiency of cobots with the dexterity of human workers, achieving a smooth and efficient assembly process.

4. Testing

Cobots can perform critical quality assurance tasks such as fold testing for smartphone screens and touch detection tests. They are equipped with specialized sensors and tools to evaluate screen durability, measure folding resistance, and check touch responsiveness. This automation ensures that screens meet performance standards and helps identify any issues before products reach consumers.

MG400 Testing Phones Interface

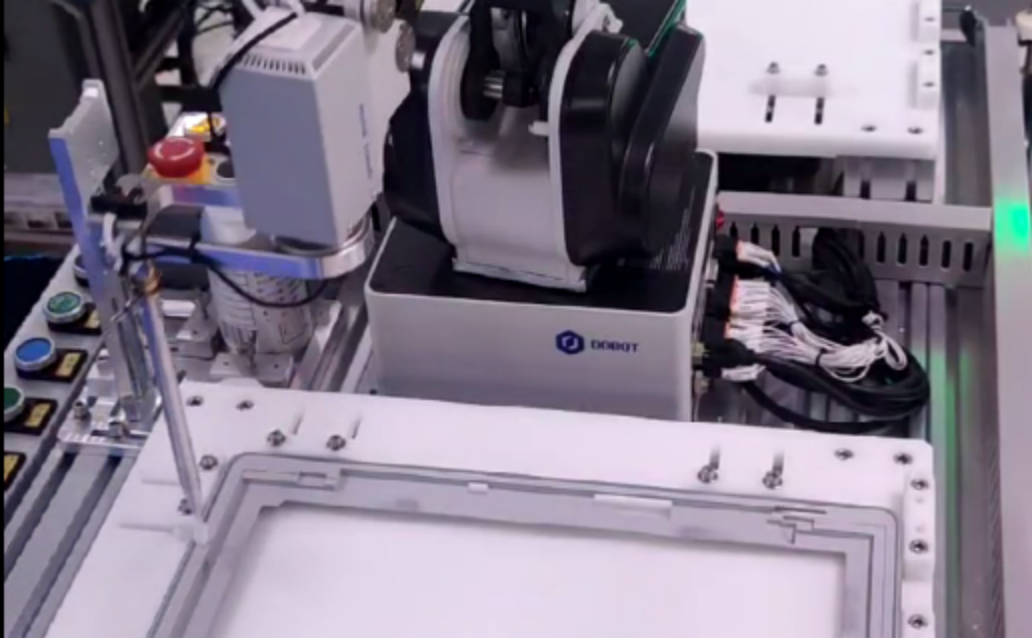

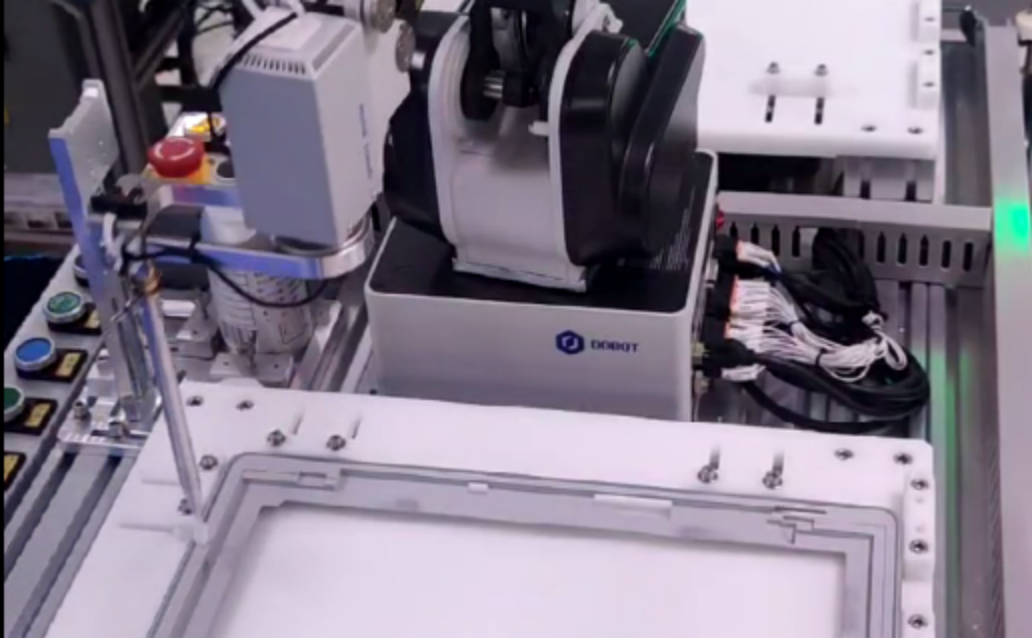

5. Gluing

Cobots equipped with gluing kits handle the application of adhesive to specific areas, such as the edges of tablet computer housings. Using vibration suppression algorithms and TrueMotion kinematic algorithms, cobots maintain stable speed and accuracy even during curved movements. This capability is particularly useful for small-batch and diverse automated production, ensuring precise and consistent application of glue for high-quality finished products.

6. Inspection

Equipped with cameras or other processing systems, cobots can execute tasks such as measuring dimensions, visual inspections, and checking soldering quality. This ensures that each product meets reliability and consistency standards before proceeding to the next stage.

7. Labeling

Cobots use integrated labeling systems to apply labels to products. They can accurately place and adhere labels to the designated areas on each item, ensuring proper alignment and reducing the risk of mislabeling.

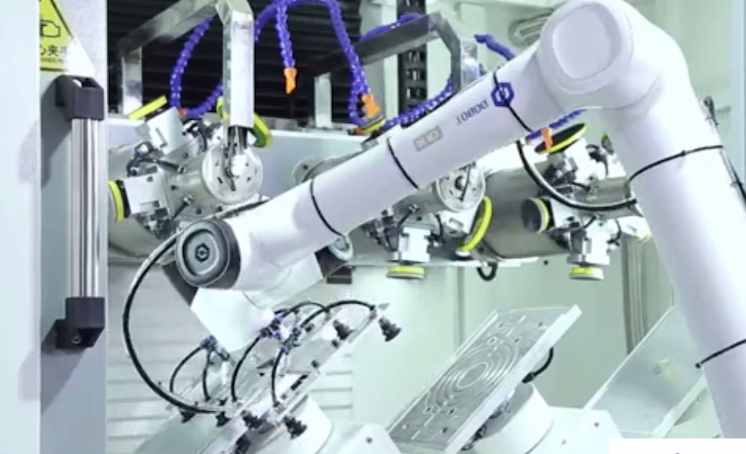

8. Grinding

Cobots equipped with grinding systems can handle the entire grinding process. They manage product loading, perform grinding operations, change sandpaper and unload the finished products. This capability ensures consistent surface finishing and high-quality results throughout the grinding process.

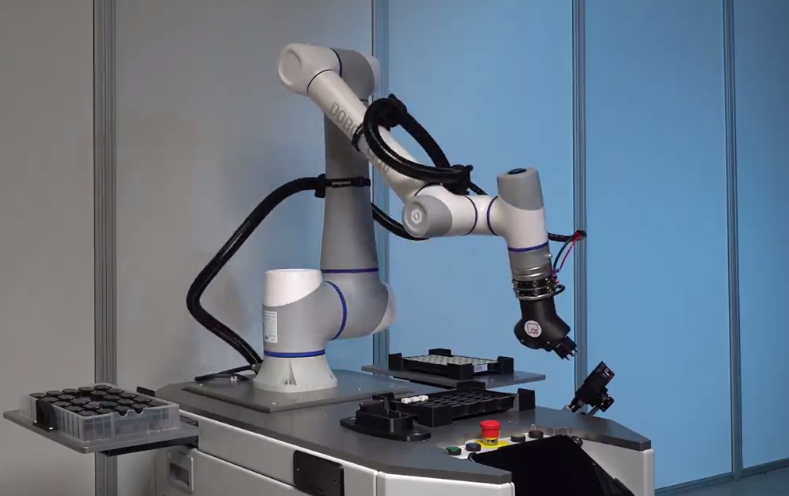

From sorting and screwdriving to assembly, testing, and beyond, Dobot cobots offer a compact and versatile solution and seamlessly fit into existing production lines in 3C manufacturing. By taking on repetitive, precision-demanding tasks, Dobot cobots enable companies to achieve unprecedented levels of efficiency, quality, and consistency.

The giants of the 3C industry have already harnessed the power of cobots to transform their operations and meet the demands of a fast-paced market. The question is: are you ready to keep the pace?