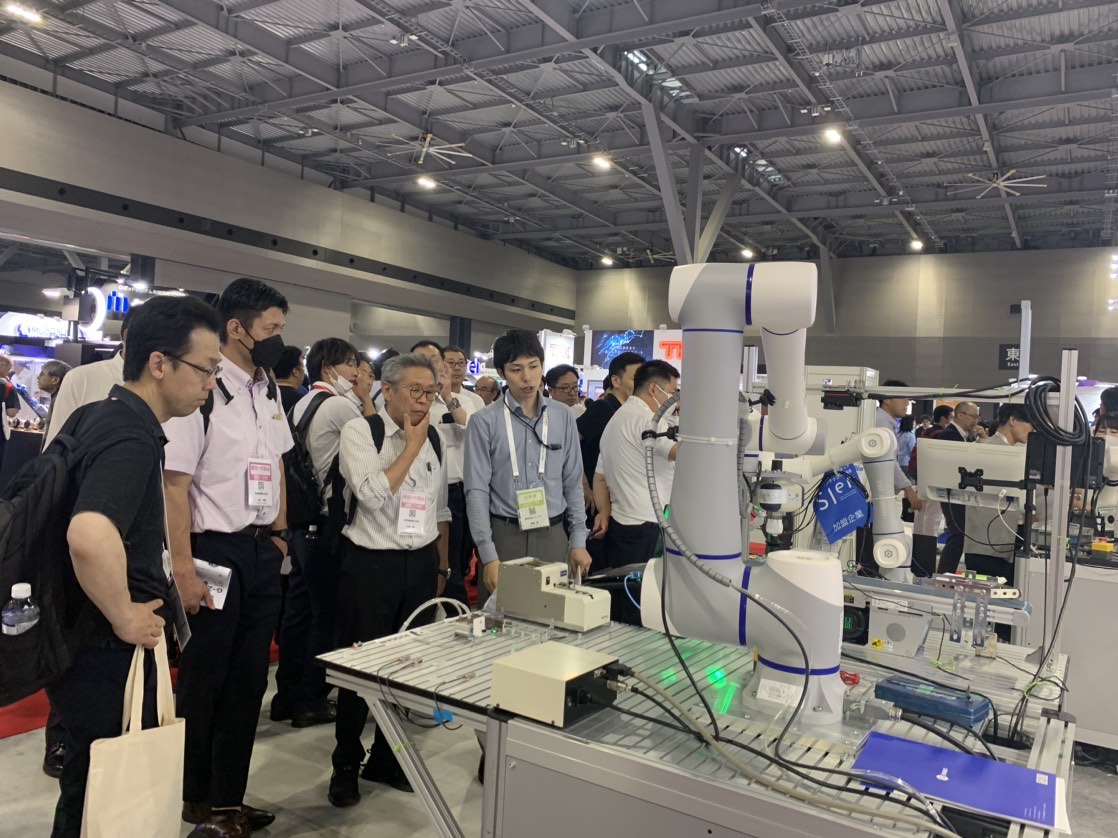

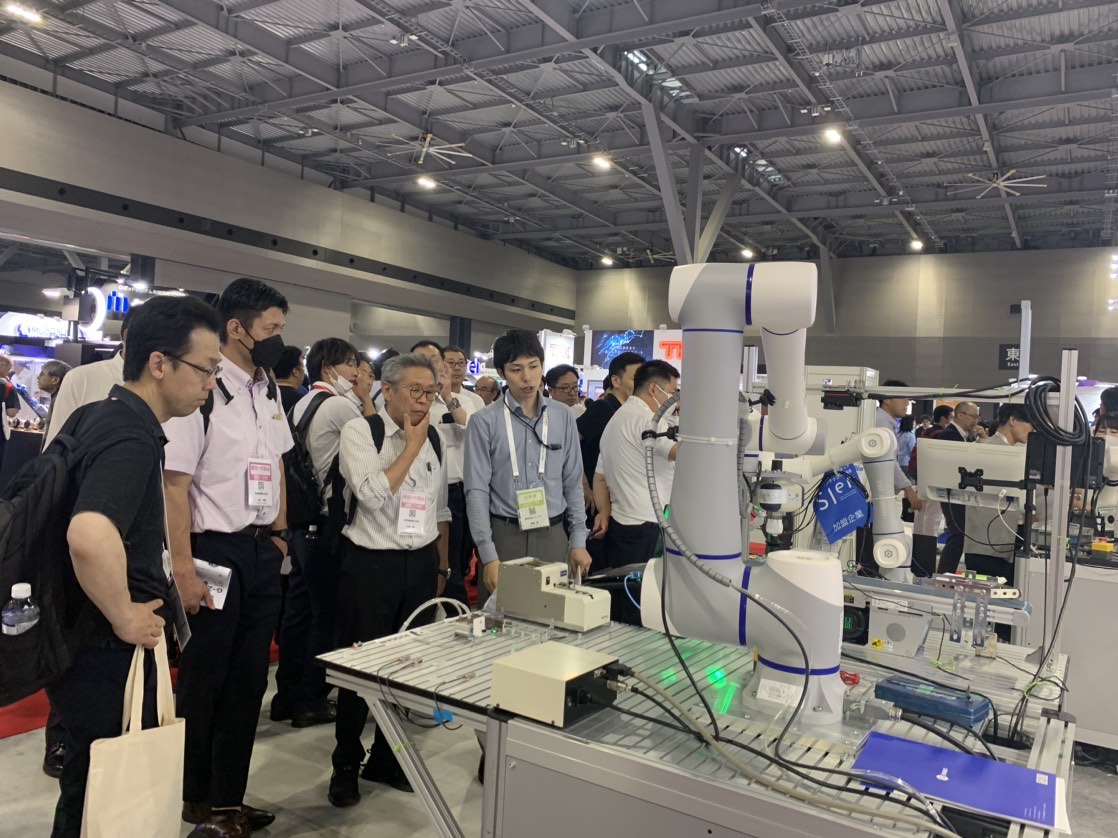

July 4-6, 2024, Dobot participated in the robotics technology exhibition "Robot Technology Japan 2024" held at the Aichi Sky Expo in Nagoya, Japan. As a global company deeply devoted to “ Make Automation Accessible”, a range of innovative robotic products and integrated solutions showcased for participants, which are designed to enhance productivity, flexibility, and intelligence on the factory floor.

Addressing Palletizing Efficiency and Density

The integrated palletizing workcell featuring Dobot's AMMR collaborative robot addresses the challenges manufacturers face with labor shortages and the need to optimize palletizing workflows. The AMMR system, built around Dobot's CR20A cobot, automatically picks, orients, and stacks boxed products onto pallets, enabling efficient, high-density palletizing that can alleviate the reliance on manual labor.

AMMR System Applied in Palletizing Solution

Versatile Liquid Dispensing and Part Handling

The versatility of Dobot's DOBOT MG400 4-axis industrial robot is highlighted in handling a variety of small to medium-sized parts and components. This includes demonstrations of the MG400's precise liquid dispensing capabilities for automated adhesive, sealant, and coating application tasks, as well as its high-speed, high-precision pick-and-place abilities. These capabilities address manufacturers' needs for flexible, accurate robotic solutions to streamline their material handling and component assembly workflows.

DOBOT MG400 Cobot for Liquid Dispensing

Intelligent Vision-Guided Sorting

A challenging sorting application using Dobot's CR5S 6-axis collaborative robot integrated with advanced 3D vision AI is set up. The system is able to accurately identify, grasp, and sort a mix of mirrored and transparent work pieces - showcasing the robot's ability to tackle complex part handling tasks with intelligence and precision. This demonstration highlights how Dobot's robotic and vision technologies can enable more versatile and reliable sorting automation for manufacturers.

DOBOT CR5S Cobot Performs in 3D Vision AI

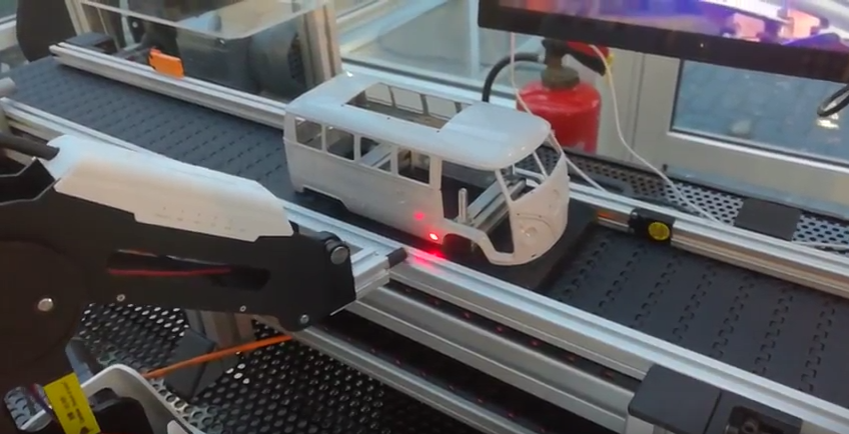

Streamlined Assembly and Transport

To meet the combined demand in assembly and transport applications, manufactures are more prefer to seek a comprehensive yet flexible solution to fit their multiple needs in various applications. An integrated assembly and transport system centered around Dobot's CR10 collaborative robot is also demonstrated. The CR10 is programmed to pick parts from a storage rack, securely fasten them together with precision screwdriving, and then place the assembled product onto a delivery cart - providing a complete automated solution for common industrial assembly workflows. This showcase addresses manufacturers' needs to improve the efficiency, quality, and traceability of their assembly operations.

Assemby & Transport System with DOBOT CR10 Cobot

"Robot Technology Japan 2024 provided an excellent platform for Dobot to showcase our latest industrial robotics innovations to the Japanese market.” said Jun Jie Xie, Head of the Dobot Japan Branch, interviewed by the prominent industry publication Robot Digest Japan, “ As a company deeply engaged in the automation industry for many years, we were gratified to see so many major Japanese enterprises already utilizing our robotic solutions and providing very positive feedback. This underscores the tremendous growth opportunities for Dobot in Japan, and we look forward to building upon the strong connections and momentum gained at this event to further expand our presence and partnerships across the country."

Jun Jie Xie, Head of the Dobot Japan Branch, was Interviewed by Robot Digest Japan

Through demonstrating these advanced robotic technologies, Dobot aimed to inspire Japanese manufacturers and system integrators to adopt more flexible, efficient, and intelligent automation solutions in their operations. Dobot is committed to delivering high-performance, safe, and easy-to-use robotic products that can help enhance productivity, quality, and competitiveness across diverse industrial sectors.