14 October 2023 – Dobot is excited to announce the release of its upgraded Versatile Welding Solution, designed to enhance welding quality and throughput across a wide range of applications. Welding scenarios can vary greatly, from automotive assembly and electronics manufacturing to metal fabrication and small-batch production. Each of these tasks presents unique challenges, requiring precise control, adaptability, and efficiency.

The Dobot Welding Solution optimizes the weld path for higher quality welds by incorporating advanced features such as Touch Sensing and Through-Arc Seam Tracking. These innovations provide a more intuitive user experience, allowing operators to achieve consistent results while minimizing the complexities often associated with welding tasks.

Explore Enhanced Features in Dobot Welding Process Package

The upgraded Dobot Welding Solution introduces a range of practical features designed to making welding automation easier and more effective than ever:

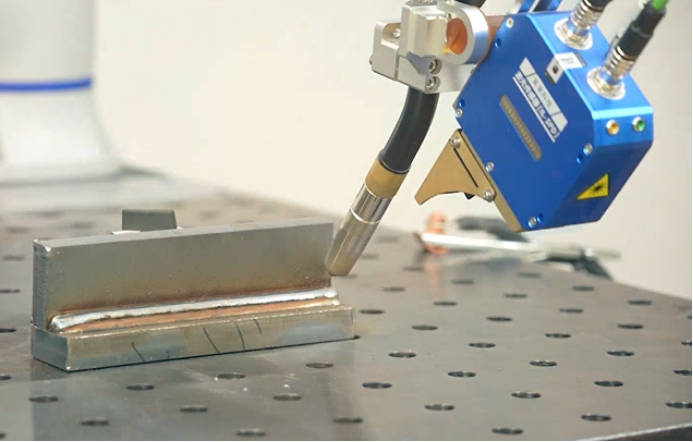

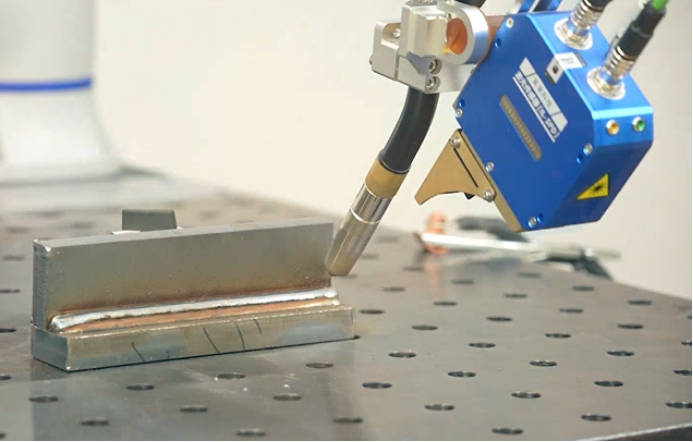

- Multi-layer Multi-pass Welding: This feature allows for repeated welding of the same area to increase weld width, ensuring robust connections.

Multi-layer Welding with Dobot Welding Process Package

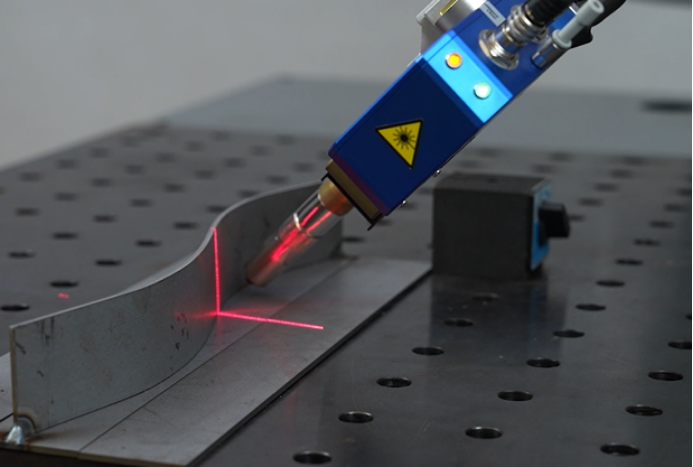

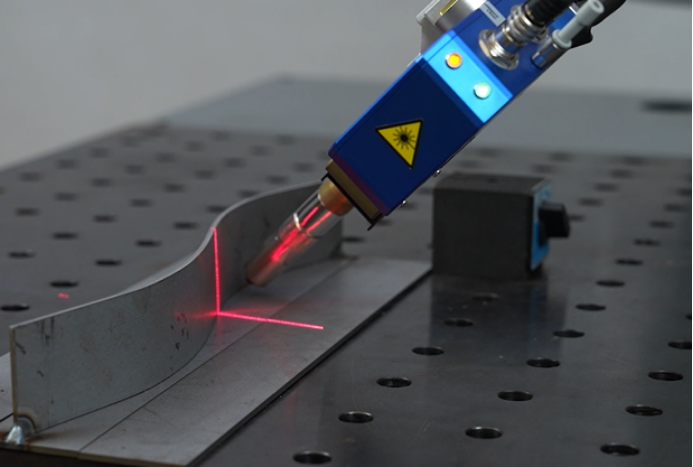

- Laser Positioning for Multi-shape Workpieces: A laser sensor scans the workpiece to accurately determine the weld position, compensating for any deviations.

Inner and Outer Diameter Laser Welding

- Touch Positioning for Multi-Dimension Welding: Touch sensing detects the location of a welding workpiece by utilizing voltage sensing and programmed torch sweeps, ensuring accurate placement before welding begins. The welding wire acts as a probe, searching for the part in a specified direction and applying a shift value to the original location. This functionality helps overcome challenges such as poor part alignment, bad joint fit-up, and inconsistent joint geometry, leading to more reliable weld.

3D+ (three-dimensional with one flat and one direction) Touch Positioning

- TAST Tracking (Through-arc Seam Tracking): This feature is ideal for thick plate welding, as it maintains a consistent relationship between the welding wire and the workpiece. The robot receives live feedback from the welder, allowing it to weave across the joint while calculating the average amperage. Based on this real-time feedback, the robot adjusts its position to compensate for any misalignments or thermal deformations. This dynamic adjustment helps mitigate issues such as part distortion and variations between parts, ensuring that each joint is welded with the correct bead appearance and depth...

Through-arc Seam Tracking with Dobot Process Package

- Laser Tracking: This capability calculates positional deviations between the welding machine and the laser sensor, adjusting the welding machine's position for precision, especially useful for heat-sensitive components or large workpieces.

Laser Tracking on Irregular Workpieces

User-Friendly and Effortlessly Accessible

1. Easy to deploy

The complex welding systems require significant human resources and expertise, leading to increased labor costs and operational inefficiencies. Dobot's All-in-One Welding Solution simplifies the welding process, making it accessible even for beginners. Integrated with a workstation, robotic arm, controller, and magnetic base, the system is designed for easy assembly and setup.

2. Quick Start and User-Friendly

With its Plug-and-Play functionality, users can get started with welding in just three steps using the Dobot Welding Process Package software. The blocky programming interface is intuitive, allowing for quick customization of various welding tasks. The drag-to-teach feature enables users to easily set welding trajectories by moving the robotic arm to define points, enhancing the overall user experience.

3. New Accessory: Convenient Welding Control Box for Basic Welding Needs

In conjunction with this release, Dobot has also launched the Welding Control Box, perfect for small-batch welding tasks that frequently switch between products and require simplicity and flexibility. This control box features a user-friendly tablet interface that allows for quick teaching and operation, enabling frontline workers to start in just five minutes. This design lowers the barrier to entry and further simplifies the welding process.

Set up the Welding Trajectory at Your Fingertips

Tailor-made Solutions for Varied Welding Scenarios

Welding applications can vary widely, with some projects involving large components while others focus on smaller parts. These diverse requirements can limit the effectiveness of traditional cobot welding solutions.

1. Dobot Mobile Welding Platform

To address these challenges, the Dobot Welding Solution offers both a Mobile Welding Platform and a Mobile Magnetic Welding Solution. The Mobile Welding Platform utilizes the Dobot CR10A Cobot as its motion mechanism, featuring easy setup and flexibility for movement. With threaded holes evenly distributed across the surface, this platform allows for secure positioning of the cobot and is compatible with various welding machines from major brands worldwide. The Dobot Welding Process Package enables users to quickly customize welding schemes for small-batch and diverse production needs.

Dobot Mobile Welding Platform for Flexible Movement

2. Dobot Mobile Magnetic Welding Solution

The Mobile Magnetic Welding Solution, equipped with a magnetic base, integrates seamlessly with the Dobot CR5A Cobot, providing a compact and flexible option for welding near workpieces. This solution is perfect for small-batch, non-standard custom workpieces that require low precision and diverse specifications.

Dobot Mobile Magnetic Base for Quickly Starting the Tasks

Dobot’s upgraded Versatile Welding Solution evolves a shop’s operations but also shows that automation doesn’t have to be complicated to enhance efficiency and throughput with Dobot Process Package, making it an ideal choice for businesses looking to enhance their operations.

About Dobot

Founded in 2015, Dobot is one of the leading global providers of collaborative robots and the creator of desktop-grade robotic arms. Dobot has developed core technologies in-house, including Integrated Drive and Control, Smart Interaction, High-performance Motion Control, Safety, Intelligent Sensing, etc, at the forefront globally.

Dobot offers a comprehensive lineup of solutions for industrial, retail, and educational sectors, driving smart production and industry upgrades, bridging industry and academics to prepare talents for tomorrow.

As the No.1 collaborative robot exporter in China, over 72,000 Dobot cobots have been deployed in automation across more than 80 countries and regions, trusted by Fortune 500 companies worldwide.

With a sound global network in the United States, Germany, Japan and other countries, Dobot ensures comprehensive service and technical support for customers around the world.

Dobot Website

www.dobot-robots.com

Marketing Contact

marketing@dobot-robots.com

%202019.jpg)