Automating your palletizing process can bring significant efficiency and cost savings to your operations. However, getting started with an automated palletizer can seem daunting. How do you train your existing staff to adapt to the robotic palletizer for the first time? Here is the guide for you.

Understand Collaborative Robots (Cobots)

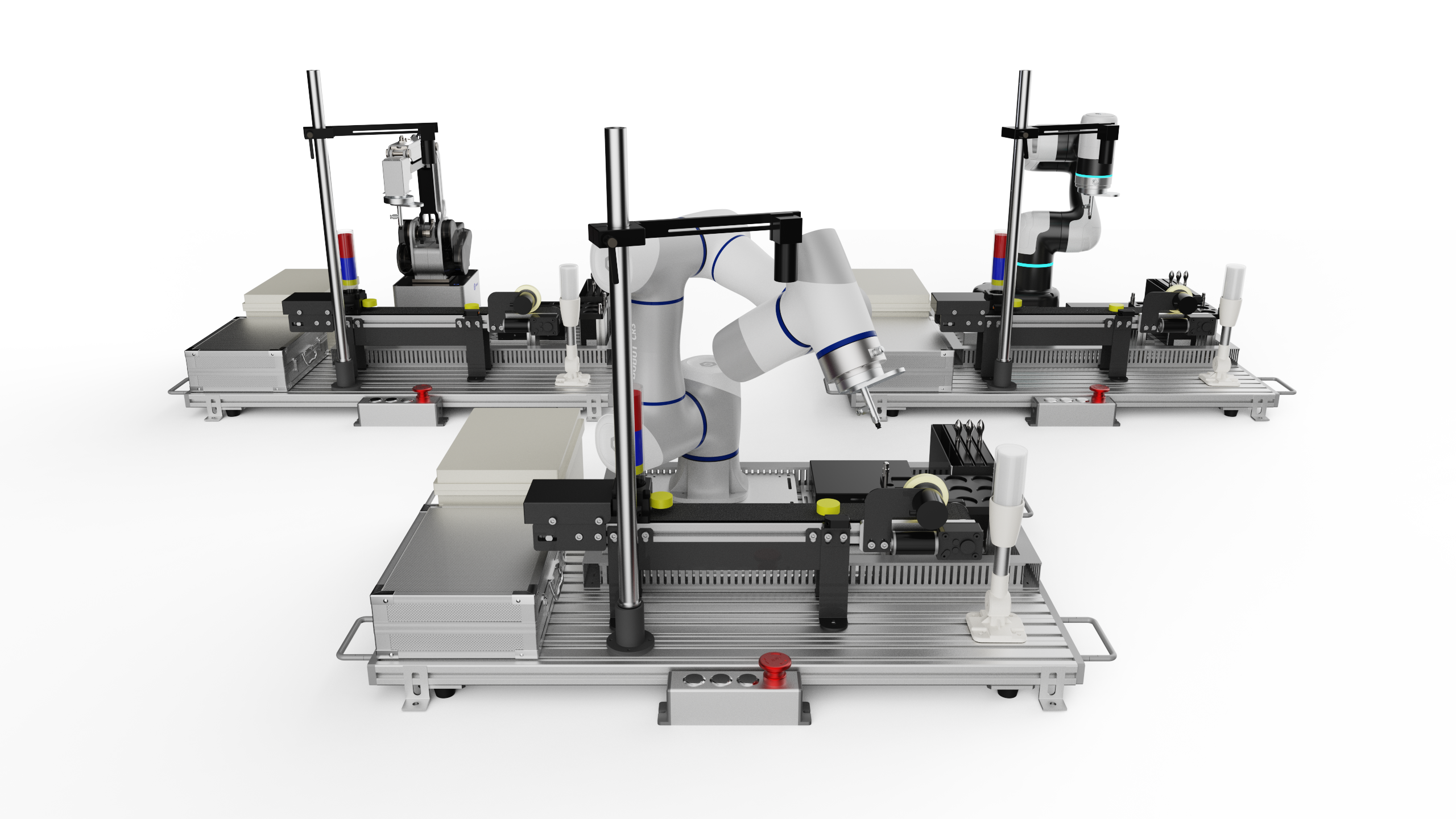

The first step in getting started with an automated palletizer is to familiarize yourself with collaborative robots, or "cobots." Cobots are a new generation of robots designed to work safely alongside human workers. Unlike traditional industrial robots, cobots are lightweight, easily programmable, and packed with advanced safety features. This makes them an ideal solution for automating palletizing tasks.

Cobots can be easily integrated into your existing workflow without the need for extensive guarding or safety caging. Their user-friendly interfaces also make them accessible for operators with minimal technical expertise. By leveraging cobot technology, you can automate your palletizing process while maintaining a collaborative work environment.

Evaluate Your Operating Process and Workflow

Before selecting a robotics palletizer, it's important to carefully evaluate your current operating process and workflow.

1. Payload Capacity: Determine the weight and size of the items you need to palletize. This will help you choose a cobot with the appropriate payload capacity. The CRA Series for example, can bear a maximum weight of 20kg.

Here are the questions for yourself:

- Are you always palletizing the same kinds of products, or do you require flexibility and redeployment capability?

- What is your required throughput?

- What are your maximum weight requirements?

- What are your future plans - do you need to build scalability into your system?

2. Consider the Floorspace:

3. Safety Requirements: Assess the safety considerations in your workspace. Cobots come equipped with advanced safety features, but you may need to integrate additional safeguards depending on your specific application. Dobot SafeSkin is the only mass-produced contactless detection. Dobot has over 20 safety strategies to protect users.

4. Stacking Patterns: Analyze the stacking patterns required for your products. Automated palletizers can be programmed to handle a wide range of stacking configurations, so it's important to understand your needs. Based on 8 two-dimensional arrangement and combination algorithms, an automatic stacking arrangement is performed using the size parameters of the cargo box and pallet.

Software and Hardware

Finally, you'll need to select the appropriate software and hardware for your automated palletizer. Look for end-effectors designed specifically for palletizing tasks, such as vacuum grippers or clamps. Additionally, consider investing in a dedicated palletizing software platform, like the Dobot Palletizing Software, which can simplify programming and optimize your palletizing operations.

By carefully considering these key factors, you can successfully implement a robotics palletizer that seamlessly integrates into your existing workflow and delivers tangible benefits to your business.