As we navigate the rapidly changing landscape of vocational education, the necessity to equip students with technical skills that align with industry demands has never been more critical. Recent studies indicate that over 70% of manufacturers are adopting automation technologies, creating a significant talent gap for skilled workers who can operate and interact with these advanced systems.

For students aiming to work in environments where they will collaborate with robots on production lines, it is essential to understand not only how to operate these machines but also how to install, program, and maintain them. This is where the integration of industrial-grade educational robots into vocational training programs becomes invaluable.

The Role of Educational Robots in Vocational Training

Educational robots designed for industrial applications can simulate a variety of scenarios that students will encounter in real-world factory settings. By incorporating these robots into the curriculum, vocational schools can provide hands-on experience that enhances students' technical abilities and prepares them for the workforce.

Key Benefits of Using Educational Robots

- Practical Experience: Students gain firsthand experience in programming, operating, and troubleshooting robots, making them more attractive to potential employers.

- Simulation of Real-World Scenarios: Robots can mimic different industrial applications, allowing students to practice in environments that closely resemble their future workplaces.

- Interdisciplinary Learning: Working with robots often involves knowledge from various fields, including electronics, mechanics, and computer programming, fostering a well-rounded skill set.

- Collaboration Skills: Students learn to work collaboratively with robots and within teams, enhancing their communication and problem-solving skills.

See How Educational Robots Simulate the Real-word Tasks in Industry

1. Assembly Line Simulation

Educational robots can replicate assembly line tasks to teach students about workflow optimization. The educational robot can be programmed to assemble components of a product, allowing students to analyze the process and identify bottlenecks. This experience helps students understand the importance of efficiency in production and the role of automation in enhancing productivity.

Simulate the 4 Major Automotive Production Process:

Stamping, Welding, Painting, and Assembly

2. Programming and Automation

Through practical programming exercises, students can learn how to automate various tasks. For instance, they can use educational robots to write code that controls the robot's movements and actions. This not only enhances their programming skills but also familiarizes them with essential software technologies used in modern manufacturing.

Practical Programming Exercise with Dobot’s Cobots

3. Quality Control

In quality assurance, robots can simulate inspection processes where students learn to evaluate products against industry standards. For example, a robot equipped with sensors can check the dimensions and quality of finished goods, providing real-time feedback. This application not only teaches students how to conduct quality checks but also emphasizes the significance of maintaining high standards in manufacturing.

4. Material Handling

Robots can demonstrate automated material handling systems by simulating the movement of goods within a warehouse or factory. Students can learn about logistics and supply chain management by programming a robot to transport materials from one location to another. This hands-on experience provides insights into the efficiency and accuracy of automated systems in managing inventory.

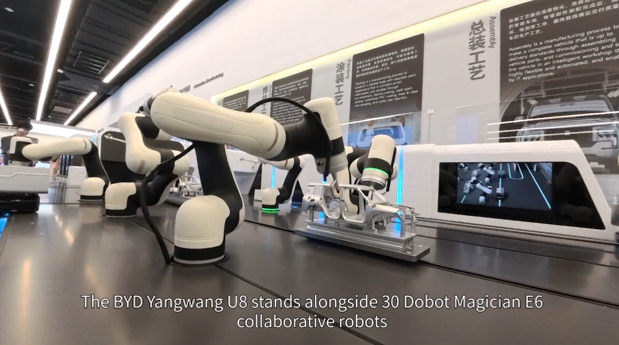

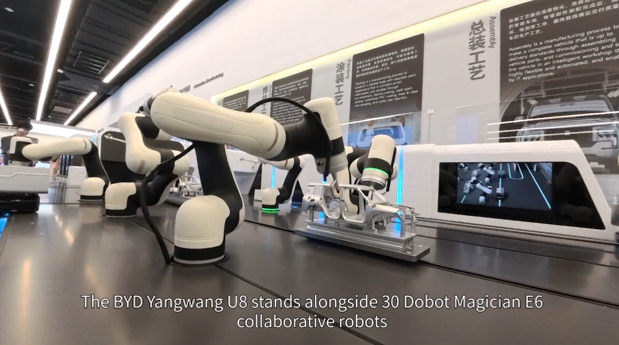

Simulate the BYD Assembly Automotive Production Line with DOBOT Magician E6

5. Maintenance and Troubleshooting

Educational robots can be programmed to simulate common malfunctions, allowing students to practice diagnostic and repair skills. For example, a robot might be designed to exhibit specific errors, prompting students to troubleshoot and resolve the issues. This hands-on experience is vital for teaching students how to maintain operational efficiency in real-world settings.

Preparing for Automated Tomorrow

As we look ahead, it’s clear that the workforce of the future will be shaped by automation. By preparing students with the necessary skills, knowledge, and experience, educators can ensure they are ready to embrace the opportunities that come with this transformation.

The key to a successful automated future lies in proactive education. By focusing on technical skills, interdisciplinary learning, and real-world applications, we can empower our students to not only adapt to change but to lead it. Preparing students for an automated future is not just about technology; it’s about fostering a mindset of innovation and adaptability that will serve them throughout their careers.