3D printing is a process where you can use a machine to create a three-dimensional object by adding material. 3D printing belongs to additive manufacturing. Built objects in small layers and the objects will be accumulated on top of each other one at once. The 3D printing process may be slow, but it does have many advantages. In the market, there are different 3D printers, suitable for professionals, educators, hobbyists, etc.

In case you start a journey to 3D printing, we have prepared a 3D printer ultimate guide along with helpful reviews.

To solve this question, we researched the following parameters based on the user experience of various types of 3D printers: print quality, build quality, reliability, ease of use, print failure rate, community, running cost, software. 3D printers vary a lot on features and cost.

Content

1. Printer Type

2. Technology Insights

3. Application Insights

4. Printing Materials

5. Top 5 Powerful 3D printers

6. How to 3D print with a versatile 3D printer

7. 3D Printing Future

There are industrial and desktop printers. Industrial printers are applied to electronic engineering, automobile, space, national defense, medical treatments, and other areas. There is also an increasing demand for designing,

prototyping, and tooling in industrial verticals. It has taken up the largest market share and is expected to occupy the future market.

Compared with industrial printers, desktop printers are easier for amateur and small companies to operate. This type of printer is starting to attract indoors, especially from the household to domestic segments. Furthermore, desktop printers can be used for educational purposes. They have been introduced to the educational field, like institutes, schools, and universities. We can see 3D printing no matter in technical training or creative education for intensive research.

How does 3D printing influence small businesses? As the market demand for creating and customizing is growing, small business is offering a service, three-dimensional printing of parts and components.

Based on technologies, the 3D printing industry has been classified as stereolithography, such as polyjet, FDM, SLS, laser metal deposition, DMLS, inkjet, EBM, digital light processing, and laminated object manufacturing. Therefore, the FDM currently accounts for the largest market share.

Easy operation of FDM is the important factor that influences the 3D printing technology to grow. Thanks to the ease of operation, FDM has increased adoption in additive manufacturing. Industry experts use these technological advancements and intensive research on several other reliable technologies.

Except for FDM, DMLS, polyjet printing, and SLS also will account for a considerable share over the forecast period. These technologies discovered applications in specific additive manufacturing fields. In addition, demand keeps rising from the aerospace & defense, medical treatment, and automobile, which also lead to the deployment of these technologies.

Based on applications, 3D Printing has been split into prototyping, tooling, and functional roles. Thanks to its high adoption of the prototyping process in several industry verticals, the prototyping segment has taken up a very large market share.

Prototyping is used to develop components, complex systems, accurate elements, especially in the automobile and aerospace sectors. This gives manufacturers a chance to achieve higher accuracy and develop reliable end products that are highly recommended for safety. As a result, the sector is expected to continue to dominate during the forecast period.

The functional parts of 3D printing are expected to enlarge at a 17.3% CAGR until 2025. The growing demand for 3D printers is also likely to promote the growth of the industry in both designing and building functional parts. Small joints and other connecting metal components of the equipment are included in functional parts.

Just like the existence of hundreds of 3D printer types, sizes, and prices, there are a lot of printing materials on the market (filament for FDM machines). There are two basic materials, including ABS and PLA.

Polylactic acid (PLA) is a biodegradable plastic, that stemmed from reproducible resources, such as Saccharum officinarum or cornstarch. As a result, the seal with it gives a semi-sweet smell. This is one of the simplest materials for printing while maintaining high strength. PLA can be "vicious", which makes it prone to clogging. Make sure you follow all the manufacturer's recommendations.

Acrylonitrile butadiene styrene (ABS) is the constituent part of Lego brick. Brought from the coals, it is firm, and wear-resisting. It is not biodegradable, and printing based on this material can evaporate an intensive "burning plastic" smell. Although this may be difficult to print with, it is still one of the most popular materials. It is necessary to prevent the heated bed from frequently warping and poor bed adhesion. Parts printed with ABS can be burnished and smooth with ease.

Both PLA and ABS are available in different colors. PLA material has some translucent colors. FDM machines always use plastic filament, often provided on reels or spools of 500g (1.1 lbs) to 1kg (2.2 lbs).

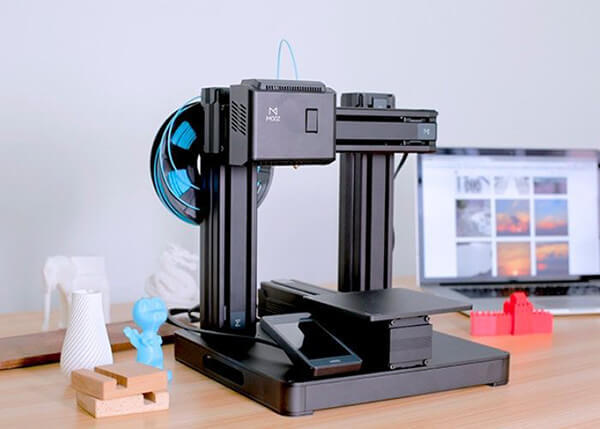

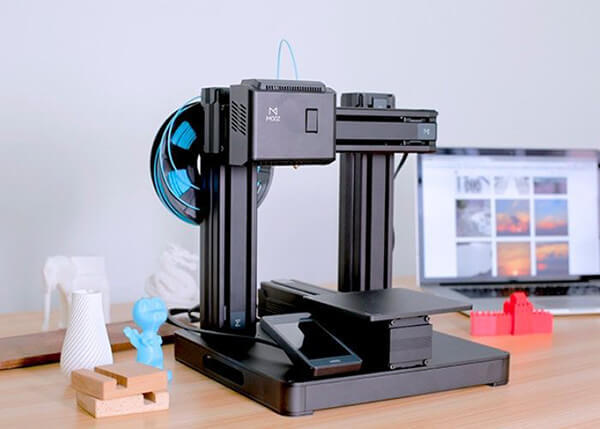

1. DOBOT Mooz

DOBOT Mooz is an industrial grade transformable metallic 3D printer, which takes an all-in-one design with interchangeable heads for 3D printing, laser engraving, and CNC carving. DOBOT Mooz is very popular among educators. It is suitable for both beginners and professionals. What makes DOBOT Mooz so unique? The industrial-grade linear guideway, advanced stepper motor, and CNC-machined body keep MOOZ stable ensuring 0.02 mm high precision.

Pros: Multifunctional 3D printer, precise print, easy to use, All-in-one device, laser engraving, CNC carving.

Cons: A bit noisy

Price: $699

2. MakerBot Replicator+

The MakerBot Replicator+ is an excellent promotion of the popular MakerBot Replicator. A new version has brought an overall improvement to nearly every part of the old version. The operation of the Replicator+ is faster and quieter while maintaining its excellent body design and safety features. This desktop 3D printer is pricy, but it can offer excellent print quality. It adopted a 1.75mm PLA filament. It is also user-friendly for home users and hobbyists to use.

Pros: Fast print speed and user-friendly design

Cons: Expensive

Price: $2499

3. Ultimaker 2+

The Ultimaker 2+ is one of the most suitable 3D printers for professional use, featured with high print quality. If you are looking for a reliable 3D printing device to manufacture 3D models, then Ultimaker 2+ may be one of the best choices for you. Its accuracy impresses a lot. However, it's not suitable for 3D printing beginners, because of its high price and complex operation approach.

Pros: High accuracy and resolution

Cons: Only for experienced professionals; complex to operate

Price: $3438

4. LulzBot Mini

If you're planning to start your 3D printing journey, then, as your first 3D printer, the LulzBot Mini is an excellent choice. It's suitable for entry-level 3D printing learners, because of its competitive price and simple manipulation. Its weak points involve low print speed. LulzBot adopts an open-source software that lacks propitiatory hardware.

Pros: Easy to use and open source

Cons: Noisy and slow print speed

Price: $1750

5. MOD-T by New Matter

MOD-T is the second generation of their low-end 3D printers manufactured by New Matter. Its design philosophy is based on home use. The printer has an easy and user-friendly design. MOD-T can provide a layer thickness of 0.05mm with a printing volume of 150 x 100 x 125 mm. Besides the abovementioned characters, MOD-T also has a filament detector and Wi-Fi module.

Pros: Competitive price and easy to use, even for beginners

Cons: Slow print speed and noisy

Price: $199

|

Brand

|

Price

|

Easy to use

|

Function

|

Time-consume

|

Application

|

|

DOBOT Mooz

|

$699

|

YES

|

3D printing/laser engraving/ CNC carving

|

Quick

|

Household & Professional

|

|

MakerBot Replicator+

|

$2499

|

YES

|

3D printing

|

Quick

|

Professional

|

|

Ultimaker 2+

|

$3438

|

NO

|

3D printing

|

Quick

|

Professional

|

|

LulzBot Mini

|

$1750

|

YES

|

3D printing

|

Slow

|

Professional

|

|

MOD-T

|

$199

|

YES

|

3D printing

|

Slow

|

Household

|

When you have your favorite 3D printer, do you know how to make high-quality 3D printing objects?

Unskilled enthusiasts can choose to download an interesting and emotional G-code to add creativity to the interior decoration. Skilled enthusiasts (you can make 3D models yourself) can create a lot of creative objects, such as stars, movie characters, and cosplay can make the corresponding models, such as Lady Gaga, Justin Biber, Taylor Swift's villain model. Like Star Wars, you can create warships and print robots. You can also print your own logo on your own T-shirt.

High-end 3D printers can print food (although the printed food is not yummy now), print auto parts, and others. Note that these high-end 3D printers cost far more than $3,000 and require skilled 3D printing experience, not suitable for most 3D print beginners.

For beginner level, designers can choose DOBOT Mooz, which is cost-effective, affordable, supports high-precision (industrial-grade) printing, and is easy to operate, allowing users to focus on design rather than printing steps. Three options are available to suit your 3D printing needs. Mooz is guaranteed. Chinese and international universities have a lot of trust in Mooz and teaching with Mooz. In addition, Mooz developers have a neural network research background and know-how to make 3D printing function well.

3D printing status: a lot of technology, not uniform, has not yet formed a set of standards. Printing accuracy varies widely, from rough printing to industrial grade. Prices, especially price/performance ratios, also vary widely. Therefore, it is recommended to choose a cost-effective printer type. If you refer to the mini easy 3D printer, then choose Dobot, with laser engraving and CNC carving function. Food printing is a recommended choice as well, but the price will be higher than $3000, with no engraving and laser functions. You should choose based on your needs and the development of team capabilities.

As an emerging technology that subverts the traditional manufacturing model, 3D printing is based on a digital model, which enables a major shift in manufacturing from equal materials to material reduction to additive production, which can effectively reduce product development costs and shorten new products development cycles. It is expected that 3D printing will be vigorously applied to the development of large-scale equipment, material diversity, outer space, deep space, etc.