Make Automation Accessible with Dobot Palletizing Solution

How cobot palletizing can help businesses fulfil objectives?

Evaluating your cobot palletizing solution is the key precondition to get started.

Single Robot Arm or All-in-One Cobot Solution?

For Choosing a Single Robot Arm Solution

It's crucial to evaluate its compatibility and integration with your existing equipment and workflows. This includes ensuring seamless connectivity with peripheral devices like external terminal panel, end-effector vacuum suction tools, etc. The robot arm should be able to easily interface and coordinate with these complementary systems to create a cohesive and efficient manufacturing process.

Additionally, assess how well the robot arm's software and control systems integrate with your current infrastructure, including software, databases, and overall ecosystem. Smooth integration with your existing systems can simplify deployment, improve efficiency, and maximize the return on your investment.

For Choosing All-in-One Cobot Solution

In contrast, an all-in-one cobot solution provides a fully integrated system where the cobot, end-of-arm tooling, and control software are all sourced from a single vendor.

- Seamless Integration: With all components designed to work together, an all-in-one cobot solution ensures a streamlined and optimized system. The integration is handled by the vendor, simplifying the deployment process.

- Ecosystem Compatibility: These comprehensive solutions are often developed with a focus on compatibility with a wide range of existing equipment, software, and workflows. This enables the cobot system to easily integrate into your current manufacturing ecosystem, minimizing disruptions and maximizing efficiency.

- Optimization and Support: By providing a complete, pre-engineered solution, the vendor can optimize the performance and capabilities of the system. Additionally, the vendor can offer comprehensive support and troubleshooting, simplifying the maintenance and upkeep of the equipment.

These Top Factors You Need to Consider

- Payload Capacity: The cobot's payload capacity needs to be able to handle the weight of your products being palletized. Underestimating the payload requirements can lead to an underpowered solution that struggles to lift and move the loads, resulting in decreased efficiency and potential product damage. The cobot should have sufficient payload capacity choices to handle your product loads.

- Reach and Work Envelope: The cobot's reach and work envelope must be sufficient to access all the necessary palletizing areas, such as the product infeed, pallet locations, and any other required zones. Ensuring the cobot has the appropriate range of motion is essential for seamless and flexible palletizing operations.

- Speed and Cycle Time: In a fast-paced manufacturing environment, the cobot's speed and cycle time can have a significant impact on your overall productivity. Look for solutions that can deliver high speeds and short cycle times to maximize the number of products palletized per minute.

- Precision and Repeatability: Consistent and accurate palletizing is critical to avoid product damage and maintain the integrity of your stacked loads. The cobot's precision and repeatability specifications should be carefully evaluated to ensure it can reliably place products in the desired positions on the pallet.

- Safety Technology: Safety should be a top priority when implementing any cobot solution. Look for advanced safety features, such as built-in collision detection, emergency stop mechanisms, and compliance with relevant safety standards. This ensures the cobot can operate alongside human workers in a collaborative environment without compromising safety.

East to Deploy for Unskilled Workers or Professionals

Palletizing Solutions for Unskilled Workers

When deploying a palletizing solution with unskilled workers, ease of use is crucial. Look for systems with a user-friendly programming interface and simplified setup, like the Dobot Palletizing Process Package that can be deployed in just 5 steps. This allows operators with minimal technical expertise to quickly learn and operate the system.

Comprehensive maintenance and support services from the vendor are also essential, ensuring the solution continues to run smoothly.

Palletizing Solutions for Unskilled Workers

For skilled manufacturing professionals, the focus can shift more to advanced programming capabilities and performance optimization. While ease of use may be less critical, access to expert maintenance and support services is still important to ensure long-term reliability.

By considering the specific needs of your workforce, you can select a palletizing solution that strikes the right balance between user-friendliness and advanced functionality.

Dobot One-Stop Palletizing Solution for Food & Beverage Industry

Does Cobot Palletizing Handle Different Tasks?

1.Completed Amount

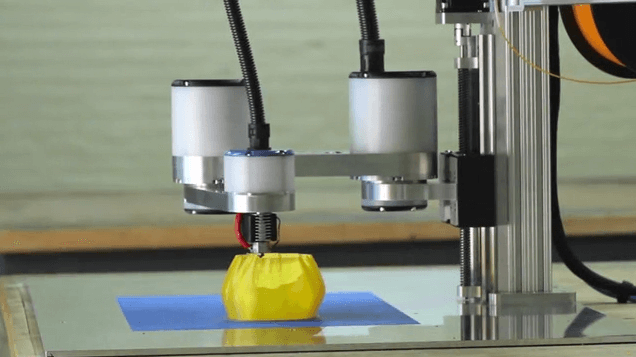

Cobot palletizing solutions offer impressive payload and height capabilities, making them suitable for a wide range of industries and applications.

The Dobot Palletizing Solution offers a maximum payload of 20kg and a maximum palletizing height of up to 2,100mm, it effortlessly meets the palletizing needs of industries such as food, beverage, and healthcare. The palletizing pace can reach 8-13 pieces per minute, with 8 pieces per minute using a single vacuum cup, and up to 13 pieces per minute with double vacuum cups. This high throughput helps maximize productivity and efficiency.

Comprehensive maintenance and support services from the vendor are also essential, ensuring the solution continues to run smoothly.

2.Different Box Sizes

Cobot palletizing systems are designed to handle a variety of box sizes and configurations.

The Dobot Palletizing Process Package includes a 3D display function that shows boxes, pallets, stack patterns, and layers in real-time 3D graphics. This feature simplifies the configuration process, allowing users to visualize the palletizing layout and make any necessary adjustments. Additionally, the 3D Simulated Palletizing function enables users to preview the deployment results, accelerating the efficiency of the process and identifying potential issues before implementation.

3.Programming

Complex programming requires professionals while is a challenge for unskilled workers. For some cobot palletizing solutions, complex programming may not be required. These systems are often designed for deployment and adjustment through parameterization, making them more accessible and user-friendly, such as Dobot Palletizing Package Process. This reduces the technical expertise needed to set up and operate the system, broadening the pool of potential operators.

In conclusion, by considering factors such as payload capacity, reach, speed, precision, and safety, businesses can evaluate and select a cobot palletizing solution that best aligns with their specific requirements, ultimately helping them fulfill their operational objectives and drive growth.