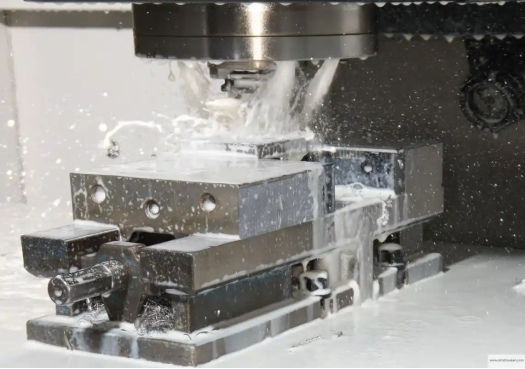

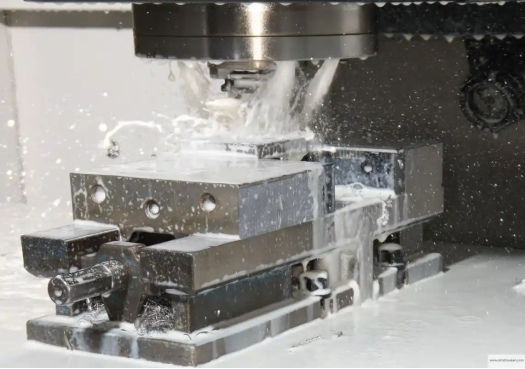

In CNC machining, equipment durability is crucial due to the harsh operating environment filled with coolant fluids, metal shavings, and dust. These elements can lead to corrosion, mechanical failures, and increased downtime, significantly impacting productivity and driving up costs.

What’s Holding Manufacturers Back for CNC Tending?

CNC machining is a cornerstone of modern manufacturing, but it comes with its own set of challenges. Here are the most common pain points faced by manufacturers:

1. Coolant Exposure

CNC machines rely on coolant fluids to reduce heat and friction during machining. However, these fluids can seep into traditional robotic arms, causing:

- Corrosion of internal components.

- Electrical failures and short circuits.

- Reduced lifespan of equipment.

2. Metal Shavings and Dust

The machining process generates significant amounts of metal shavings and dust, which can:

- Infiltrate robotic arms, leading to mechanical jams.

- Interfere with sensors, causing malfunctions.

- Increase the frequency of cleaning and maintenance.

3. Frequent Downtime

When robotic arms fail due to environmental factors, production lines come to a halt, resulting in:

- Delays in order fulfillment.

- Increased labor costs for repairs.

- Lost revenue due to reduced productivity.

These challenges highlight the need for a robotic solution that can thrive in the demanding conditions of CNC machining—a solution like the IP68-rated robotic arm.

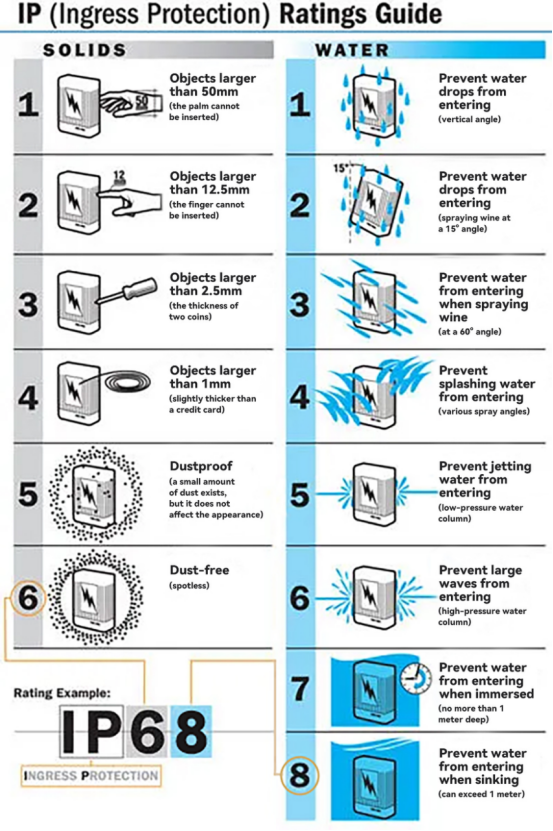

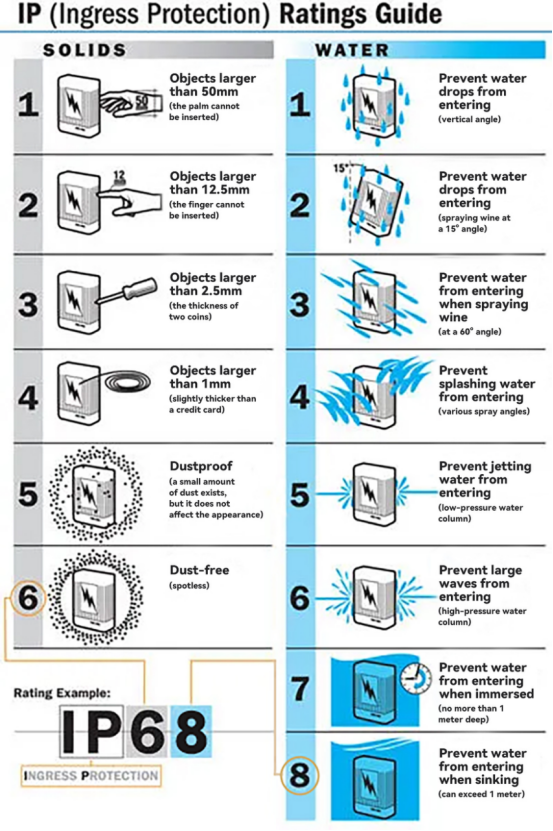

What is IP68, and How Does It Solve CNC Pain Points?

The term "IP" stands for Ingress Protection, a standard defined by the International Electrotechnical Commission (IEC). It classifies the level of protection an enclosure provides against solids (like dust) and liquids (like water).

An IP rating consists of two digits:

- The first digit (0-6) indicates protection against solids.

- The second digit (0-9) indicates protection against liquids.

For example, an IP68 rating means:

- First Digit (6): Complete protection against dust. No dust can enter the enclosure, even in the most challenging environments.

- Second Digit (8): Protection against long-term immersion in water. The device can withstand being submerged in water deeper than 1 meter, as specified by the manufacturer.

In the context of CNC machining, an IP68-rated robotic arm offers:

- Coolant Resistance: No more corrosion or electrical failures from coolant exposure.

- Dustproof Operation: Metal shavings and dust are kept out, ensuring smooth performance.

- Reduced Downtime: With robust protection against environmental factors, IP68-rated robots operate reliably, minimizing disruptions.

The challenges of CNC machining don’t have to hold your business back. With IP68-rated robotic arms, you can overcome coolant exposure, metal shavings, and frequent downtime, ensuring your production lines run smoothly and efficiently.