Have you ever thought about your costs in the palletizing process every day?

What Are the Potential Costs Hidden behind Manual Palletizing?

One of the primary drivers for adopting automated palletizing is the potential to reduce labor costs. Manual palletizing can be a physically demanding task, often requiring multiple workers to handle the heavy lifting and precise pallet loading.

To illustrate the potential labor cost savings, let's consider a hypothetical example. Assume a manual palletizing operation requires 4 workers, working 8 hours per shift, with 2 shifts per day, 6 work days per week, and a labor rate of $35 per hour. In this scenario, the monthly labor cost for manual palletizing would be $53,760 (4 workers x 2 shifts x 8 hours x $35 per hour x 24 days).

Is Automated Palletizing Expensive for the Long Term?

In contrast, an automated palletizing solution may only require 1 worker to handle the same operations. Assuming the same labor rate and shift structure, the monthly labor cost for the automated system would be $13,440 (1 worker x 2 shifts x 8 hours x $35 per hour x 24 days). This represents a monthly saving of $40,320 and a payback period of just 2 months.

Automated systems, on the other hand, can perform these tasks with speed and consistency, reducing the need for manual labor. Over time, the cost savings from reduced labor requirements can help offset the initial investment in an automated system.

Industrial Robot Palletizing or Collaborative Robot Palletizing, Which One is Your Best Chioce?

As businesses evaluate the cost-effectiveness of their palletizing operations, it's essential to consider the pros and cons of manual, industrial robot, and collaborative robot palletizing.

Industrial Robot Palletizing: Consistent but Inflexible

Industrial robot palletizing systems offer increased productivity, improved quality, and potential cost savings over time, as the reduced labor costs and increased efficiency can offset the initial investment in the robotic system. However, industrial robots are typically large, fixed-position systems that require significant time and effort to reprogram and redeploy, limiting their flexibility in adapting to changing production needs.

Collaborative Robot Palletizing: Versatile and Safeguarded

- Adaptivity:

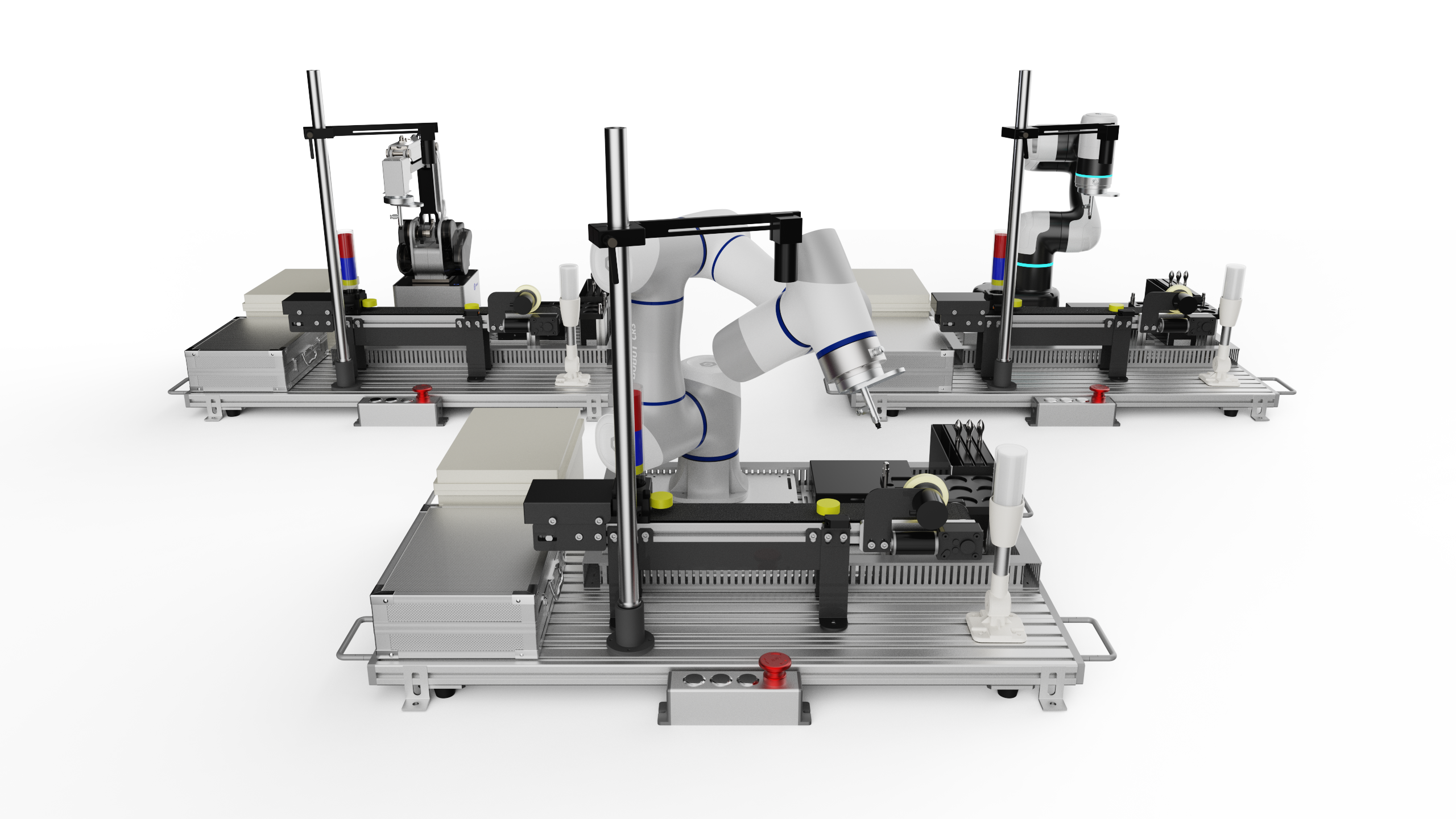

In contrast to bulky and rigid industrial robot palletizing systems, Dobot collaborative robot palletizing solution offers a highly adaptable approach. Dobot's cobots are compact, portable, and can be easily reprogrammed and redeployed to different production lines with a simple plug-and-play setup. This allows businesses to quickly adapt their palletizing operations to changing requirements and diversify their production needs with ease, unlike the more inflexible industrial robot systems.

- Safety:

Industrial robot palletizing often requires extensive fencing and guarding to isolate the robots from human workers, creating a physical barrier that limits collaboration. Dobot's cobots, on the other hand, feature advanced safety technologies that enable safe human-robot interaction without the need for physical barriers. Safeguarded by over 20 safety features, including effective electromagnetic brakes, Dobot's cobots can work alongside human operators, enhancing productivity and flexibility on the shop floor.

- Ease of Use:

Whereas industrial robot palletizing systems typically require complex programming and setup by specialized technicians, Dobot palletizing solution provides a remarkable degree of ease of use. Even workers with minimal technical expertise can readily adapt Dobot's cobots to changing production requirements through simple reprogramming and redeployment, without the need for specialized training or advanced robotics knowledge. This accessibility empowers businesses to quickly optimize their palletizing operations to meet evolving demands.

Dobot One-Stop Palletizing Solution

In conclusion, the cost-effectiveness of automated palletizing systems can be evaluated through a comprehensive analysis of factors such as labor costs, productivity, error reduction, scalability, and maintenance requirements. By carefully weighing these considerations, businesses can make an informed decision on whether investing in automated palletizing is a strategic and cost-effective solution for their operations.