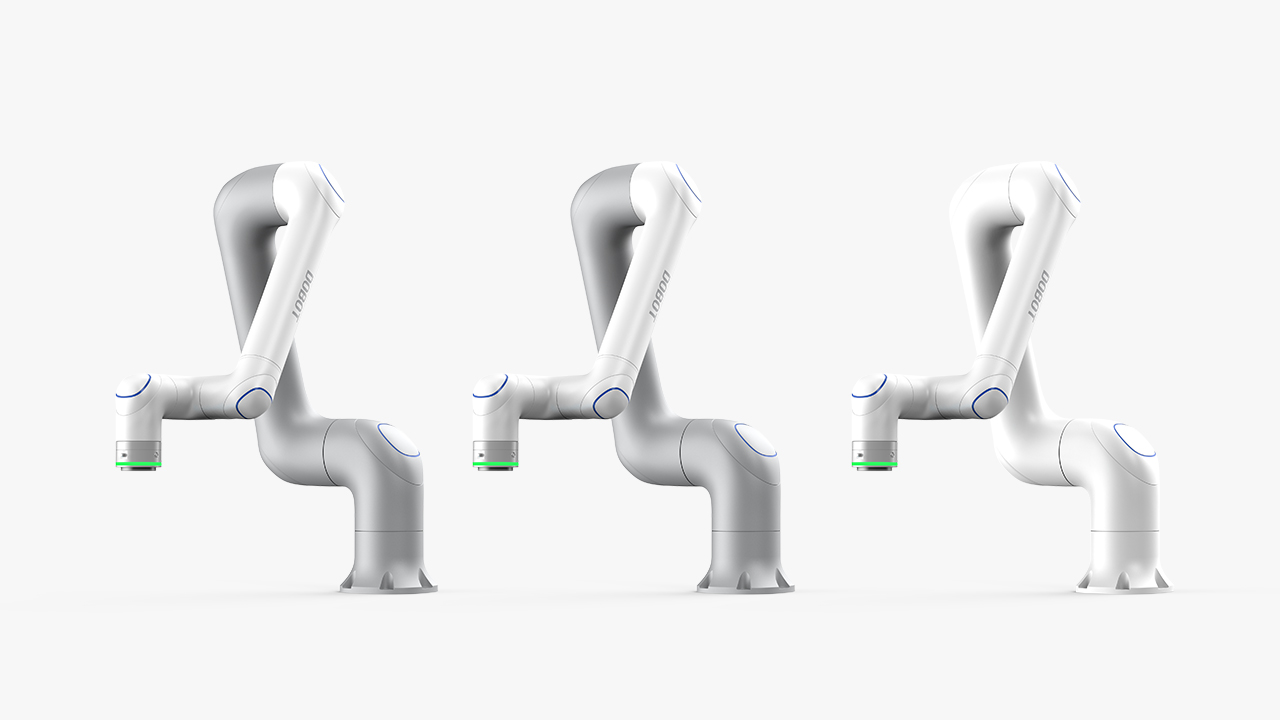

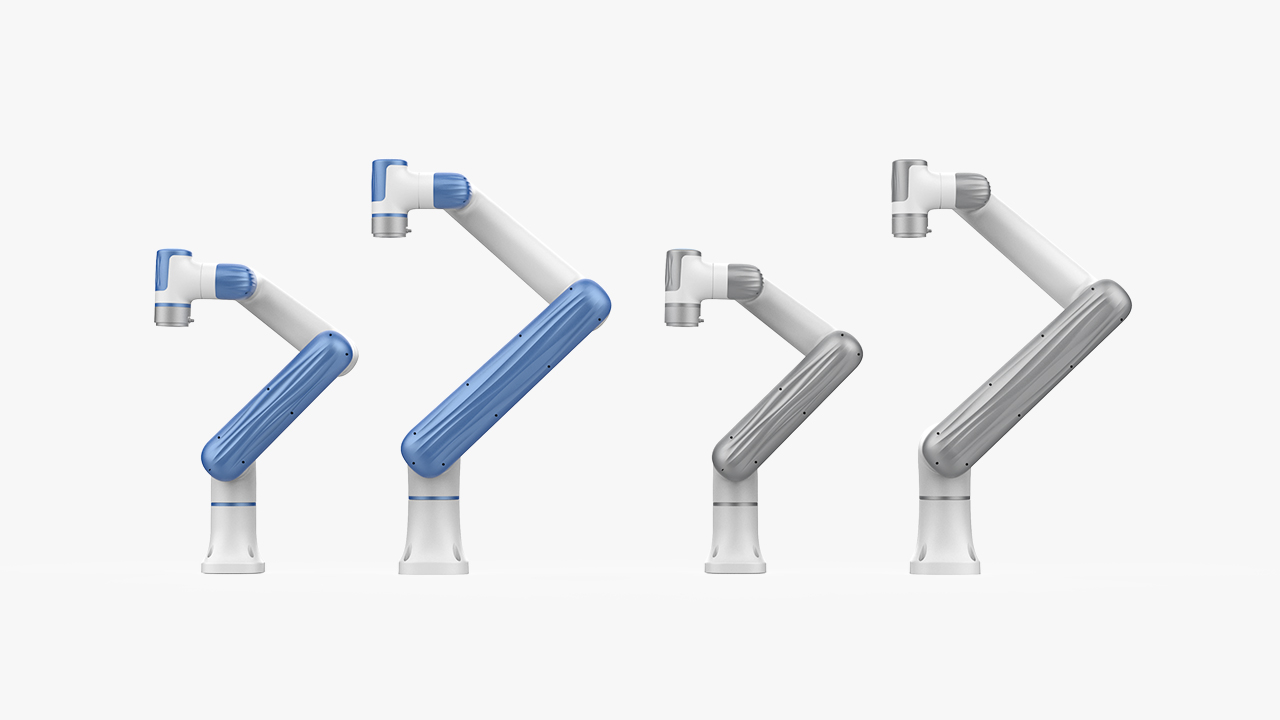

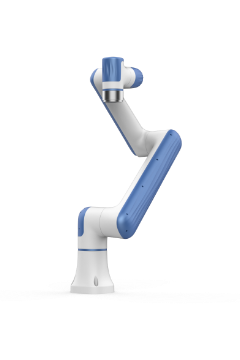

Breezy is a leading innovator in AI-driven refurbishment solutions, specializing in automating and optimizing the secondary electronics market. Partnering with ASBIS Robotic Solutions and leveraging the DOBOT Nova Series collaborative robots (cobots), Breezy implemented a cutting-edge refurbishment solution that covers sound testing, quality grading, visual inspection, sorting, and data cleaning. This advanced system has transformed a 600m² smart factory, enabling a 4-person team to manage the entire operation, achieving 70% cost savings and a 300% increase in operational efficiency.

This project not only aligns with the principles of Industry 4.0 but also paves the way for Industry 5.0, where human-machine collaboration and AI-driven automation take center stage...

- Quality Control: Ensuring consistent quality in refurbished devices.

- Labor-Intensive Processes: High reliance on manual labor leading to inefficiencies and errors.

- Scalability: Difficulty in scaling operations to meet increasing demand.

Breezy's refurbishment process was transformed through the deployment of DOBOT Nova Series cobots in several key areas:

1. Sound Testing:

- The DOBOT Nova Series cobots were equipped with specialized audio testing tools to perform precise sound quality checks on devices.

- The cobots automated the process of playing test audio files, recording device output, and analyzing sound quality using Breezy AI’s algorithms.

- This ensured consistent and accurate sound testing, eliminating human error and improving efficiency.

2. Visual Inspection:

- High-resolution cameras integrated with the cobots enabled detailed visual inspection of devices.

- The cobots scanned devices for defects such as scratches, dents, or misaligned components, capturing high-quality images for analysis.

- Breezy’s algorithms processed the images in real-time, identifying defects and categorizing devices based on quality.

3. Sorting and Grading:

- Based on the results of sound and visual tests, the DOBOT cobots sorted devices into different quality grades.

- The cobots used precise gripping mechanisms to place devices into designated bins or conveyor belts, ensuring accurate and efficient sorting.

- This automated process reduced manual handling and improved consistency in grading.

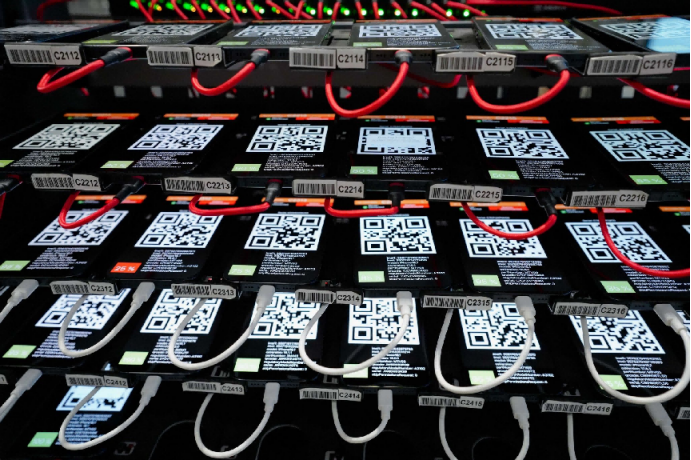

4. Data Cleaning:

- Based on the results of sound and visual tests, the DOBOT cobots sorted devices into different quality grades.

- The cobots used precise gripping mechanisms to place devices into designated bins or conveyor belts, ensuring accurate and efficient sorting.

- This automated process reduced manual handling and improved consistency in grading.

Industry 5.0: A New Era of Human-Machine Collaboration

This project exemplifies the principles of Industry 5.0, where advanced robotics and AI work in harmony with human creativity to drive innovation. By deploying the DOBOT Nova Series, Breezy and ASBIS Robotic Solutions have demonstrated how cobots can handle repetitive, precision-driven tasks, freeing human workers to focus on strategic and creative aspects of the refurbishment process.

The success of this collaboration highlights the transformative potential of Industry 5.0, where technology enhances human capabilities rather than replacing them. At Dobot, we are proud to be at the forefront of this evolution, providing solutions that empower businesses to achieve new levels of efficiency, quality, and sustainability.

.png)