Gerhard Haas GmbH & Co. KG-Rival is a prominent company specializing in manufacturing mass-produced houshold items. With a focus on innovation and efficiency, Rival has established itself as a leader in the industry. Their commitment to quality and customer satisfaction drives their operations, but they face challenges that necessitate the adoption of modern solutions.

The Business Transformation

Rival faces significant challenges in its manufacturing processes, primarily due to repetitive tasks that require standardization. The sorting, assembling, and labeling of parts consume valuable time and resources. Furthermore, the company struggles to find suitable and skilled staff amidst a labor shortage. This situation complicates their ability to cover multiple product lines, each with a variety of products, leading to inefficiencies and production delays.

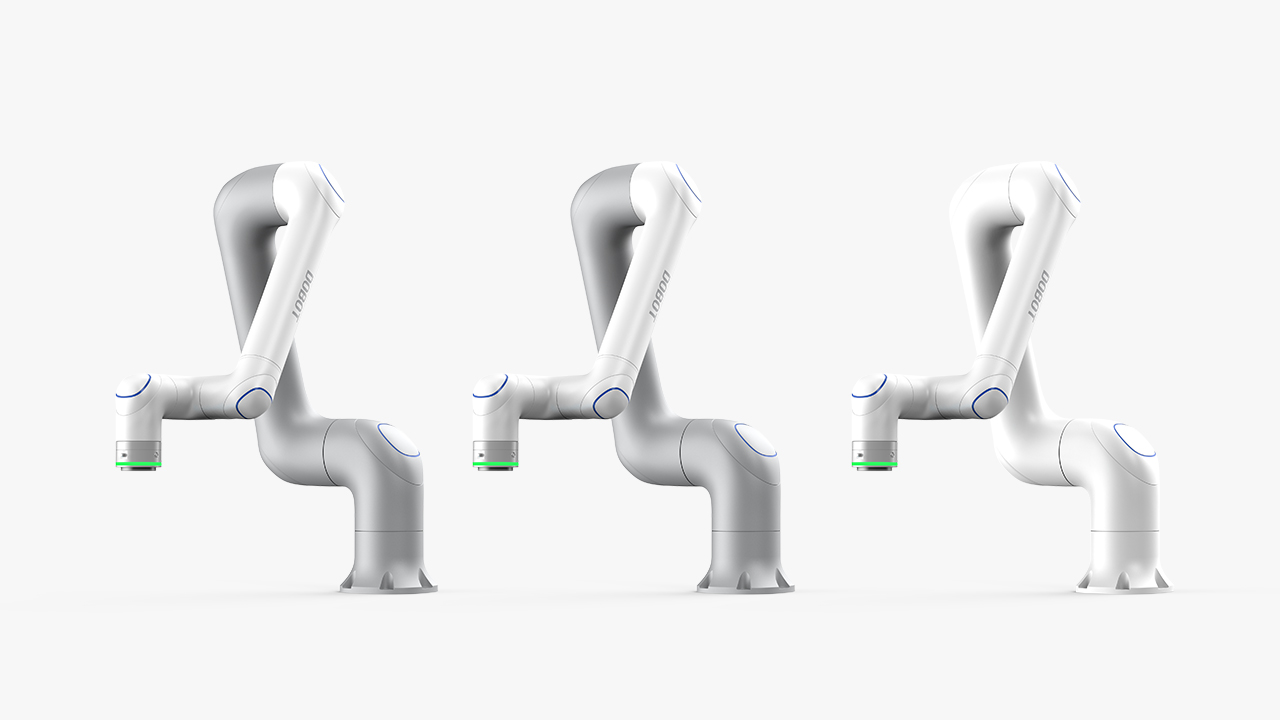

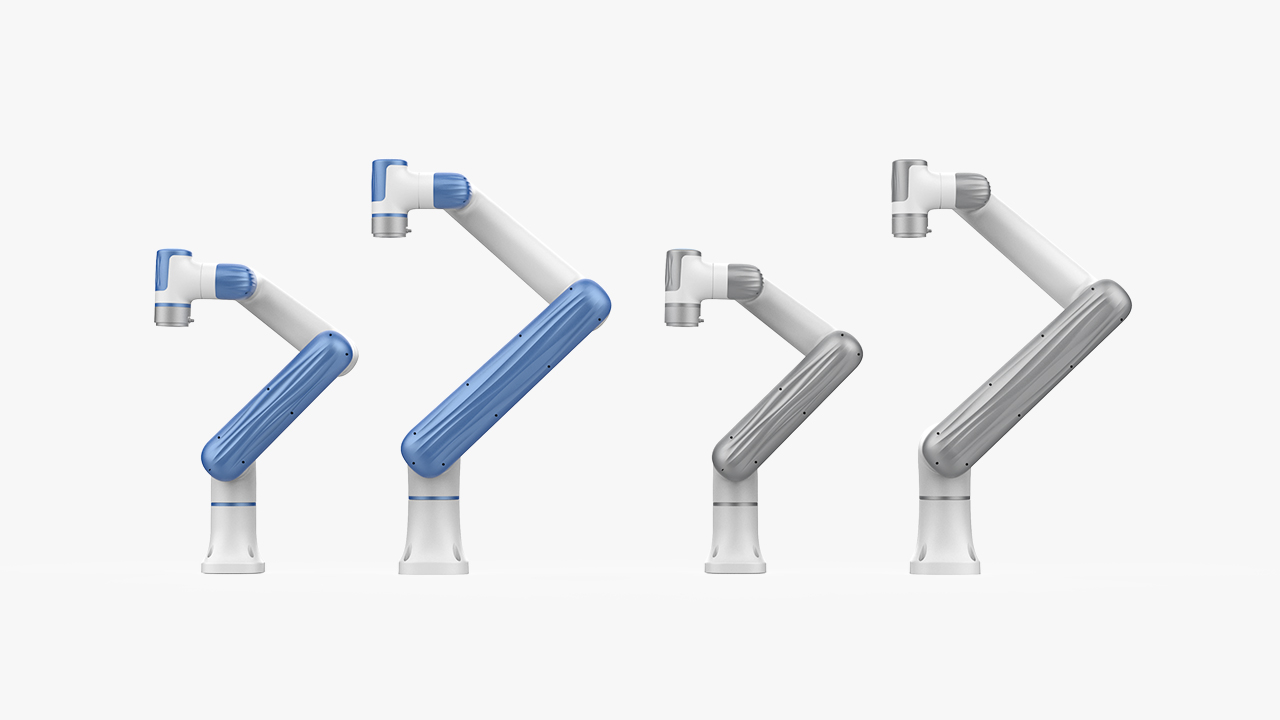

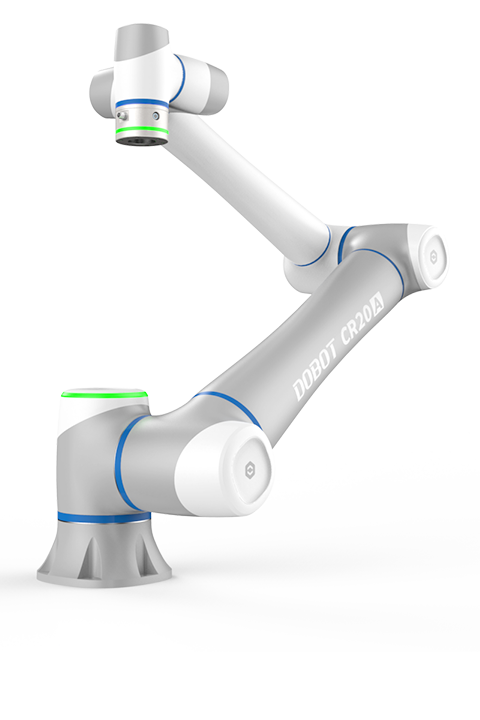

To address these challenges, Rival decided to automate its entire plant using Dobot robotic solutions with the DOBOT CRA Series. The automation process includes various applications, such as pick-and-place operations, random bin picking, and palletizing. A specific case involves the application of 18kg rollers to press them into the bottom of plastic boxes, significantly improving efficiency and consistency in production. By integrating these robotic systems, Rival can streamline its operations and enhance productivity across multiple product lines.

Easy to Use, No Skills Required

The automation of Rival's production lines has brought these benefits:

- Increased Efficiency: Automated systems can perform repetitive tasks faster and more accurately than human labor, leading to higher output and reduced cycle times.

- Reduced Labor Dependency: With robots handling the majority of labor-intensive tasks, the company can mitigate the impact of labor shortages and reduce reliance on skilled workers.

- Consistency and Quality: Automation ensures that each task is performed with precision, leading to a higher quality of the final products and minimizing errors.

- Flexibility: The robotic systems can be easily reconfigured to handle different products, allowing Rival to adapt quickly to market demands and expand its product offerings.

- Cost Savings: Over time, the reduction in labor costs and increased efficiency can lead to significant cost savings for the company.

By embracing Dobot automated solution, Gerhard Haas GmbH & Co. KG-Rival is well-positioned to overcome current challenges and thrive in a competitive market.