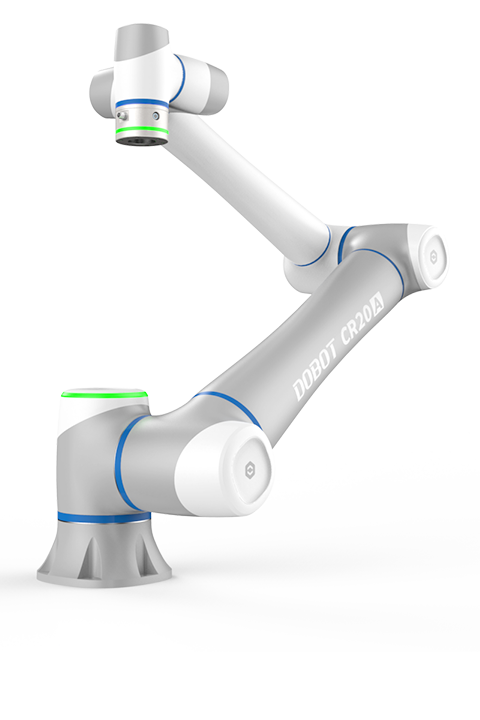

The Dobot CRA Cobot's easy-to-use programming interface allowed operators to quickly adapt the system to changing product specifications, without the need for extensive technical expertise. This flexibility, combined with the cobot's consistent welding quality, resulted in a 30% increase in MIG welding productivity for the facility. Furthermore, the Dobot CRA Cobot's advanced safety features ensured seamless human-robot collaboration, giving the facility the confidence to maximize the benefits of welding automation.