In 2023, the World Robotics Report revealed a record-breaking global industrial robot density of 141 units per 10,000 employees. Collaborative robots (cobots) are at the forefront of this transformation, with their market poised to grow at a CAGR of 25% through 2027. As cobots increasingly share workspaces with humans, ensuring safety in these environments has become a critical focus.

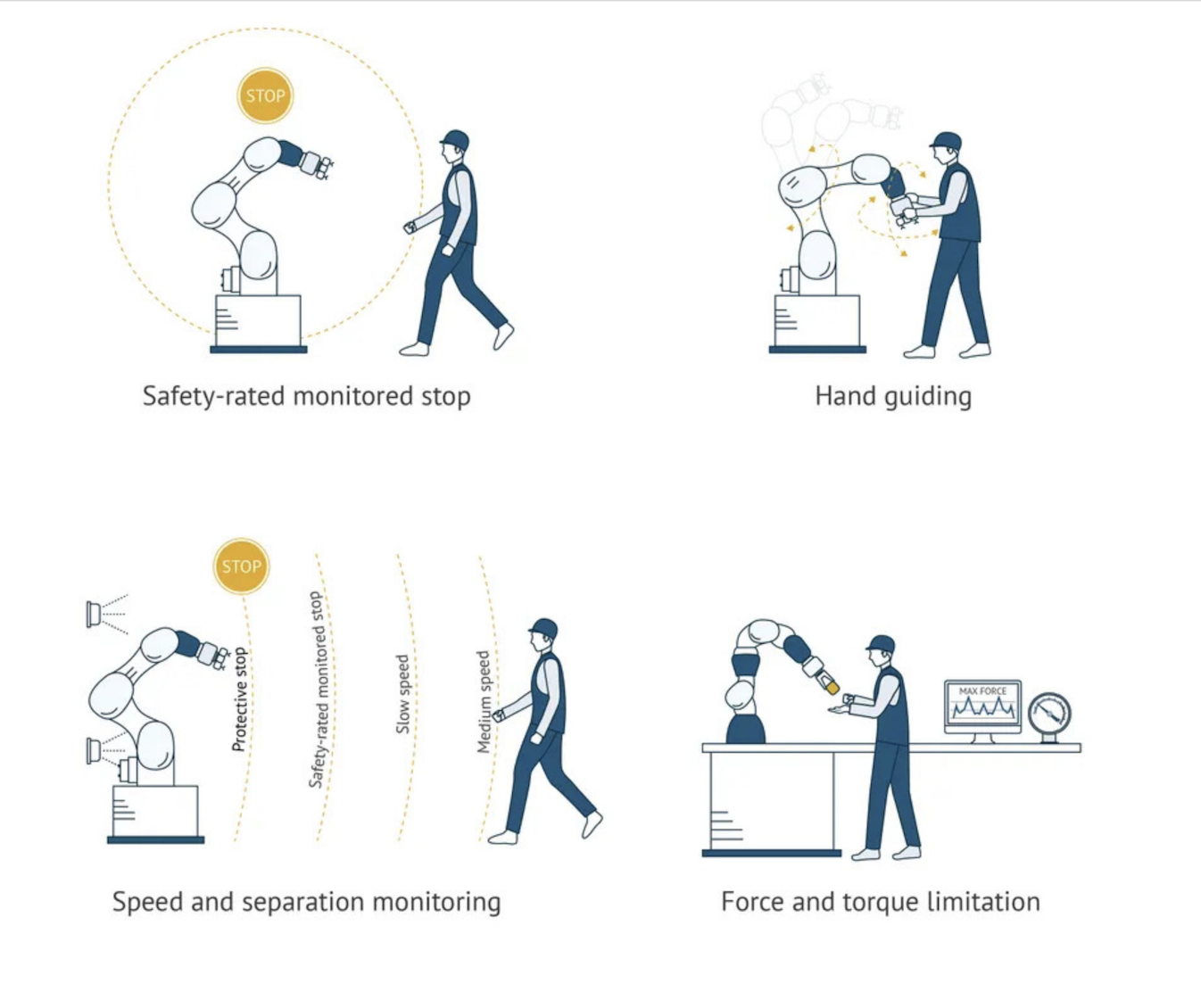

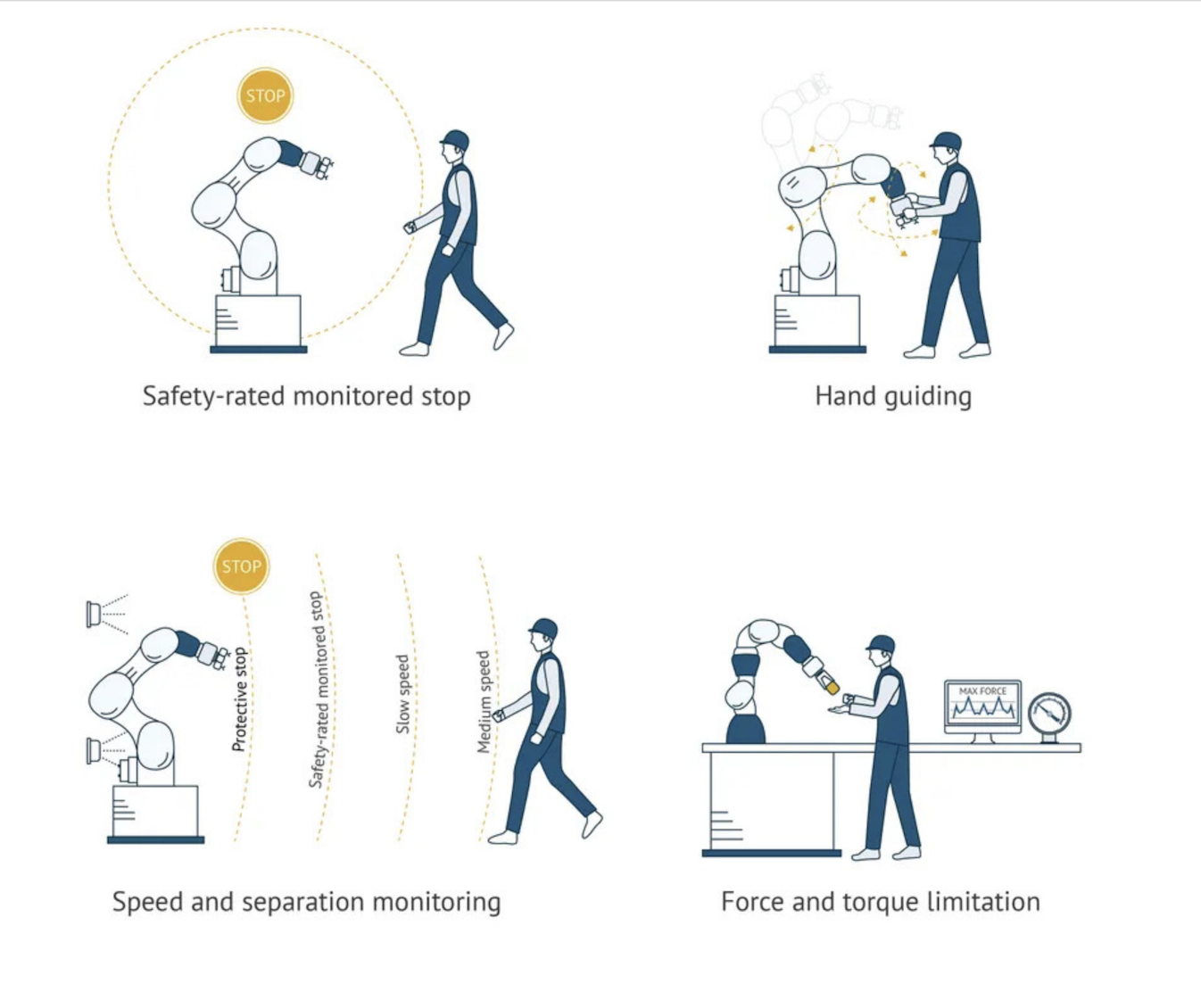

ISO 15066, a standard for collaborative robots (cobots), defines four collaborative working modes, each tailored to specific operational scenarios to balance safety and productivity.

Each of these approaches is functional, however it often forces manufacturers to choose between safety and productivity.

Dobot’s Advanced Safety Strategy: Safety Meets Efficiency

Dobot Robotics has developed a suite of innovative safety technologies that prioritize protection without sacrificing performance.

SafeSkin Technology: Proactive Collision Prevention

Dobot’s SafeSkin Technology redefines collision safety by preventing incidents before they happen.

- Higher Productivity: Unlike traditional cobots limited to speeds of 0.25 m/s for safety, SafeSkin enables speeds up to 1 m/s, achieving up to 4x efficiency in tasks like assembly and packaging.

- Reduced Downtime: Proactive obstacle detection prevents collisions, minimizing disruptions to workflows and lowering repair costs.

- Enhanced Flexibility: Adjustable sensitivity settings accommodate a variety of tasks and environments, increasing versatility.

Electromagnetic Braking: Securing Critical Operations

Power outages and emergency stops can disrupt workflows and risk product damage. Dobot’s electromagnetic braking system ensures stability under such conditions.

- Precision Product Protection: The system’s rapid response time of 18 milliseconds limits end-effector movement to just 0.95 mm, safeguarding sensitive tasks like material handling and delicate assembly.

- Operational Continuity: Maintains robotic positioning during sudden stops, minimizing accidents and material waste.

Safety Controller: A Redundant Safety Architecture

Certified to PLd Cat3 standards, Dobot’s independent safety controller ensures precision monitoring and control of robot movements.

- Comprehensive Risk Mitigation: Over 20 integrated safety features, including limits on speed, force, and joint positions, reduce the risk of injuries and equipment damage.

- Uninterrupted Reliability: A redundant architecture ensures continuous protection, even in high-stakes operations, avoiding costly downtime.

Customizable Safety Zones: Dynamic Protection for Complex Workspaces

Modern manufacturing demands adaptable safety solutions, and Dobot meets this need with virtual safety zones.

- Maximized Workspace Utilization: Virtual barriers replace physical ones, allowing safe robot operation in shared spaces and optimizing layouts.

- Improved Proximity Efficiency: Robots work closer to operators and equipment, enhancing throughput in tasks like palletizing and packaging.

A Future Where Safety and Productivity Coexist

The rise of collaborative robots is reshaping industries, but it comes with the responsibility of safeguarding human operators. Dobot’s innovative safety technologies—led by SafeSkin, pave the way for a new era of automation.

By addressing the limitations of traditional safety strategies, Dobot enables manufacturers to achieve both safety and productivity, redefining what’s possible in human-robot collaboration.