Seeking the Best Automated Palletizing Solutions? Explore the Key Certifications That Prove Their Excellence

In today's fast-paced manufacturing and logistics environments, choosing the right automated palletizing solution is crucial for enhancing efficiency and productivity.

How to Evaluate the Performance of Automated Palletizing Systems

Evaluating the capabilities of automated palletizing solutions requires a focus on specific indicators of performance, safety, and stability.

1. Performance: Ensuring Operational Excellence

When evaluating the performance of automated palletizing solutions, various certifications play a significant role:

Operational Efficiency

The CE, FCC, and NRTL certifications ensure that palletizing systems meet high standards for operational efficiency. These assessments cover energy consumption, speed, and maximum throughput, confirming that the equipment can handle demanding workloads effectively.

Electromagnetic Compatibility

Compliance with FCC, ICES, and MIC standards guarantees that automated palletizers operate without causing harmful interference to other electronic devices. This is crucial for maintaining effective communication and control in environments with multiple systems.

Functionality Under Load

Certifications such as NRTL and KC verify that equipment maintains performance levels during peak operations. They ensure that systems can respond effectively under varying load conditions, minimizing downtime and enhancing overall productivity.

2. Safety: Prioritizing Operator and System Security

Safety is a top priority in automated palletizing systems, and certifications provide essential assurances:

Risk Mitigation

The CE, NRTL, and NCC certifications assess potential risks, including mechanical hazards and electrical safety. These evaluations ensure that equipment is designed with necessary safety features, such as emergency stops and protective barriers, to prevent accidents during operation.

Electrical Safety

NRTL certification specifically focuses on electrical safety, evaluating risks such as electric shock and fire hazards. This guarantees that automated palletizing systems are built to prevent electrical failures, ensuring a safe working environment for operators.

Electromagnetic Emissions

ICES and MIC certifications ensure that equipment does not cause harmful electromagnetic interference. This compliance is critical for maintaining safety in environments where multiple electronic systems interact, protecting both personnel and other devices from potential hazards.

3. Stability: Guaranteeing Reliable Operations Over Time

Stability is crucial for the reliable operation of automated palletizing systems, and certifications attest to this quality:

Operational Reliability

Certifications such as CE, NRTL, and KC indicate that equipment has undergone rigorous testing to verify its ability to withstand operational stresses, including vibrations and temperature fluctuations. This ensures that the equipment remains functional and reliable over time.

Consistent Performance

Adherence to FCC, ICES, and MIC standards ensures that automated palletizers can operate smoothly without disruptions from electromagnetic interference. This stability is essential for maintaining consistent operations in complex manufacturing environments.

Long-Term Durability

The stability validated by these certifications gives businesses confidence that their automated palletizing solutions will perform reliably over time, minimizing the risk of failures that could disrupt operations...

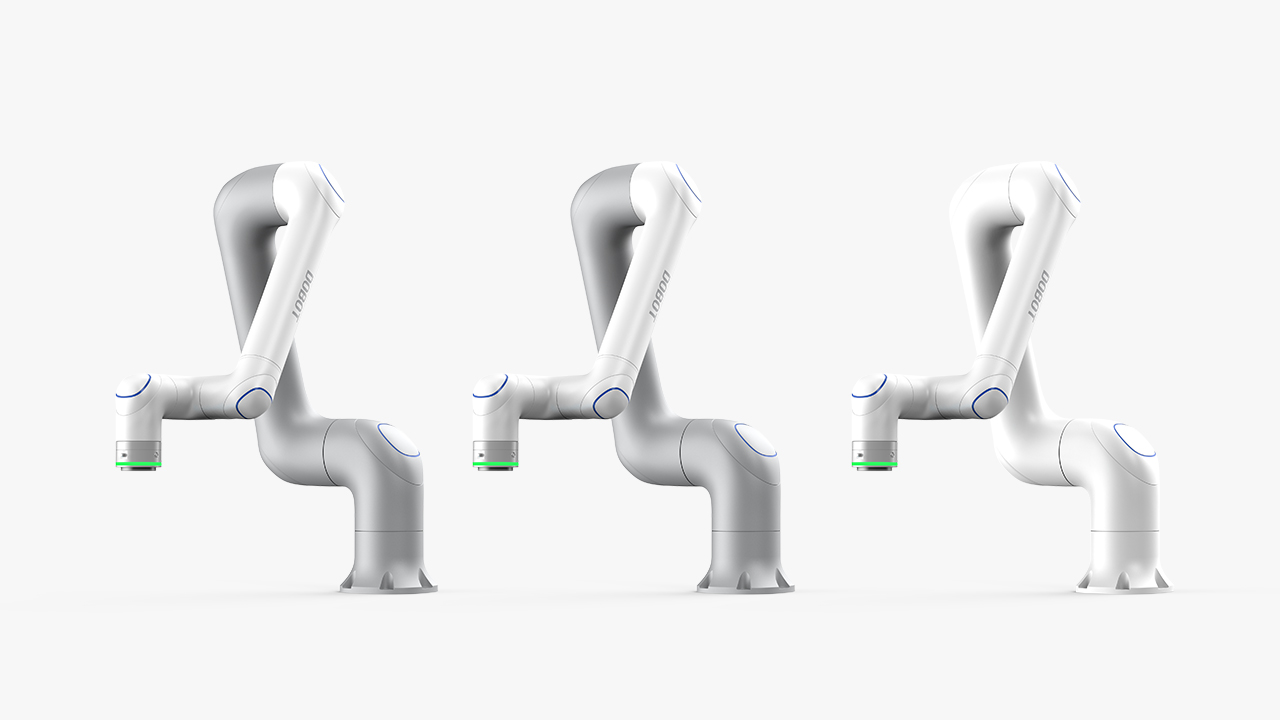

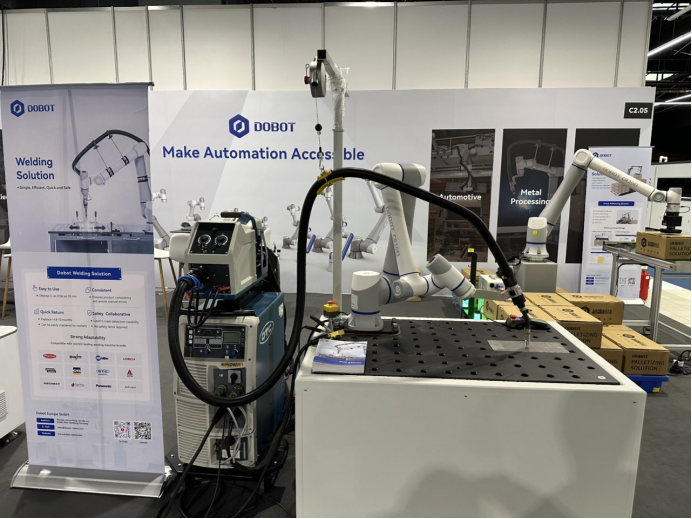

Dobot’s Palletizing Solutions: Certified for Excellence

Dobot’s turnkey palletizing solutions excel in all these categories, having achieved certifications such as CE, FCC, NRTL, and ICES. These credentials validate the systems’ operational performance, safety features, and stability under demanding conditions.

Upgraded Dobot Turnkey Palletizing Solution Has 3 Key Certifications

Incorporating certified palletizing solutions into your operations is not just about compliance; it’s about ensuring that your systems are safe, reliable, and efficient. Certifications like CE, FCC, NRTL, and ICES serve as benchmarks for quality and safety, reflecting the commitment of manufacturers to meet rigorous standards. These certifications validate the performance and safety of automated palletizing solutions, providing peace of mind for businesses and their customers. As the industry continues to evolve, staying informed about these certifications will not only enhance your operational integrity but also position your business competitively in the marketplace.